Airbus is increasing its investment in improving its infrastructures to protect the most important part of its business: aeronautical production.

The refurbishment of the roofs of most of its warehouses, in addition to improving the aesthetics of the complex, provides greater protection against the entry of water and facilitates maintenance, thus increasing the safety of the products and equipment stored and produced inside.

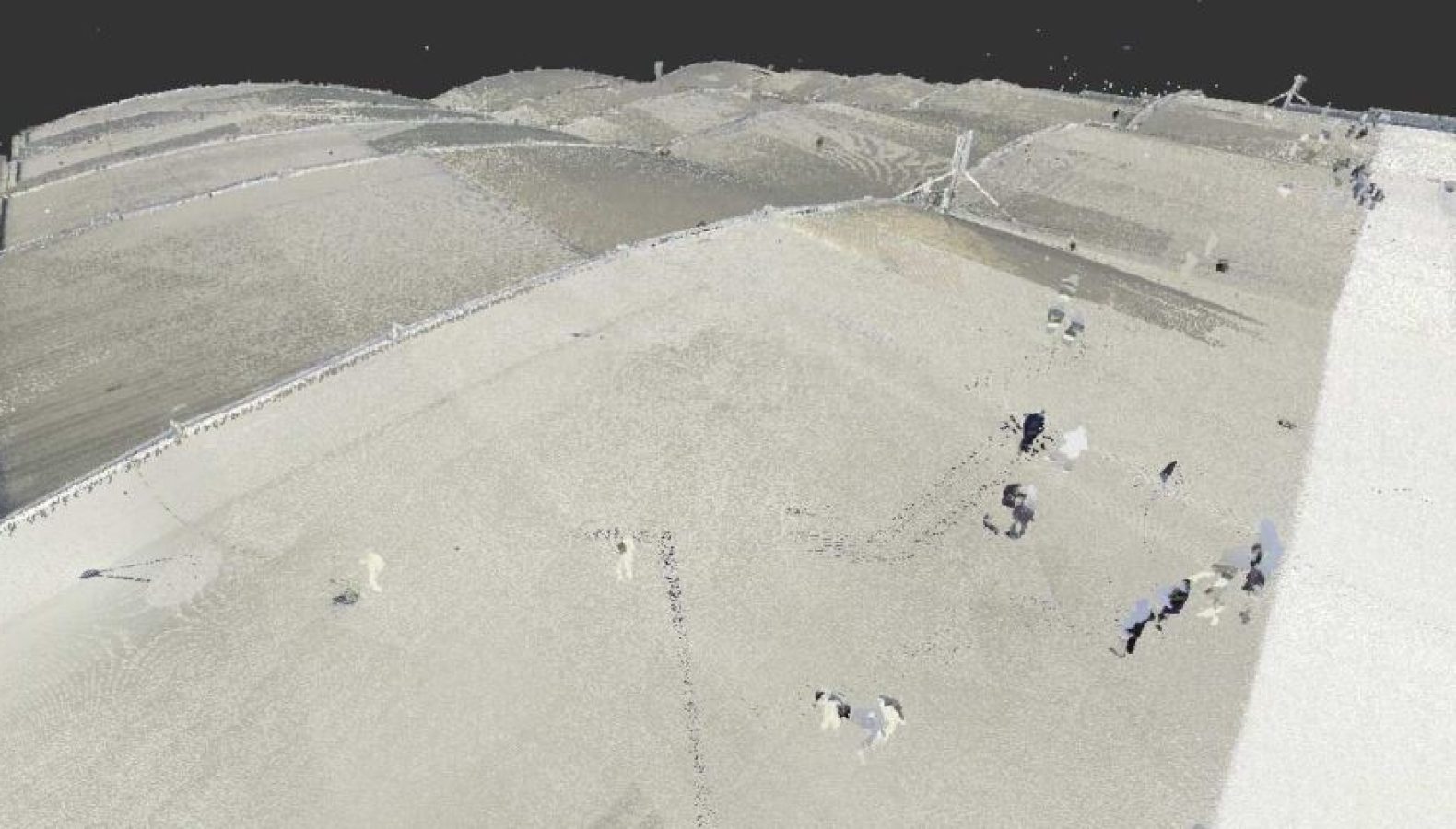

The innovative design of its roofs, formed by different lunettes, has its architectural difficulty due to the large number of elements of which they are composed and their curved shapes. The refurbishment project is a medium to long-term investment and will be carried out in several phases over two years.

Airbus entrusted Savener to develop the execution project and to provide solutions for rainwater drainage, as well as to improve the roof finishes. With the laser scanning methodology, the different roofs were virtualised, allowing for a more precise analysis of the interventions to be carried out.

Savener is currently developing the project management with the assistance of the manufacturer Danosa as a distributor of the solution, which will provide the guarantee provided by its products, ensuring the success of the intervention thanks to the fact that it always offers a team of certified installers for its systems.

Danosa is carrying out specific inspections on site to guarantee the correct use of its products, the treatment of joints, folding and welding, as well as the quality of the finishing touches, offering reports that complement the monitoring and coordination of Savener as Site Manager.

We are sure that the deep and meticulous control that is being carried out under the DF of SAVENER will result in numerous benefits for such a consolidated and important client for us as Airbus.