Savener continues to strengthen its strategic alliance with Airbus, marking a significant milestone in the development of infrastructure for the aerospace industry. On this occasion, Savener has been selected for a unique job, to design and build the mock-up of one of Airbus’ most important buildings, which will become the logistics and storage hub for Airbus Helicopters in Europe. This building will open its doors in the coming months, consolidating Airbus’ position on the continent.

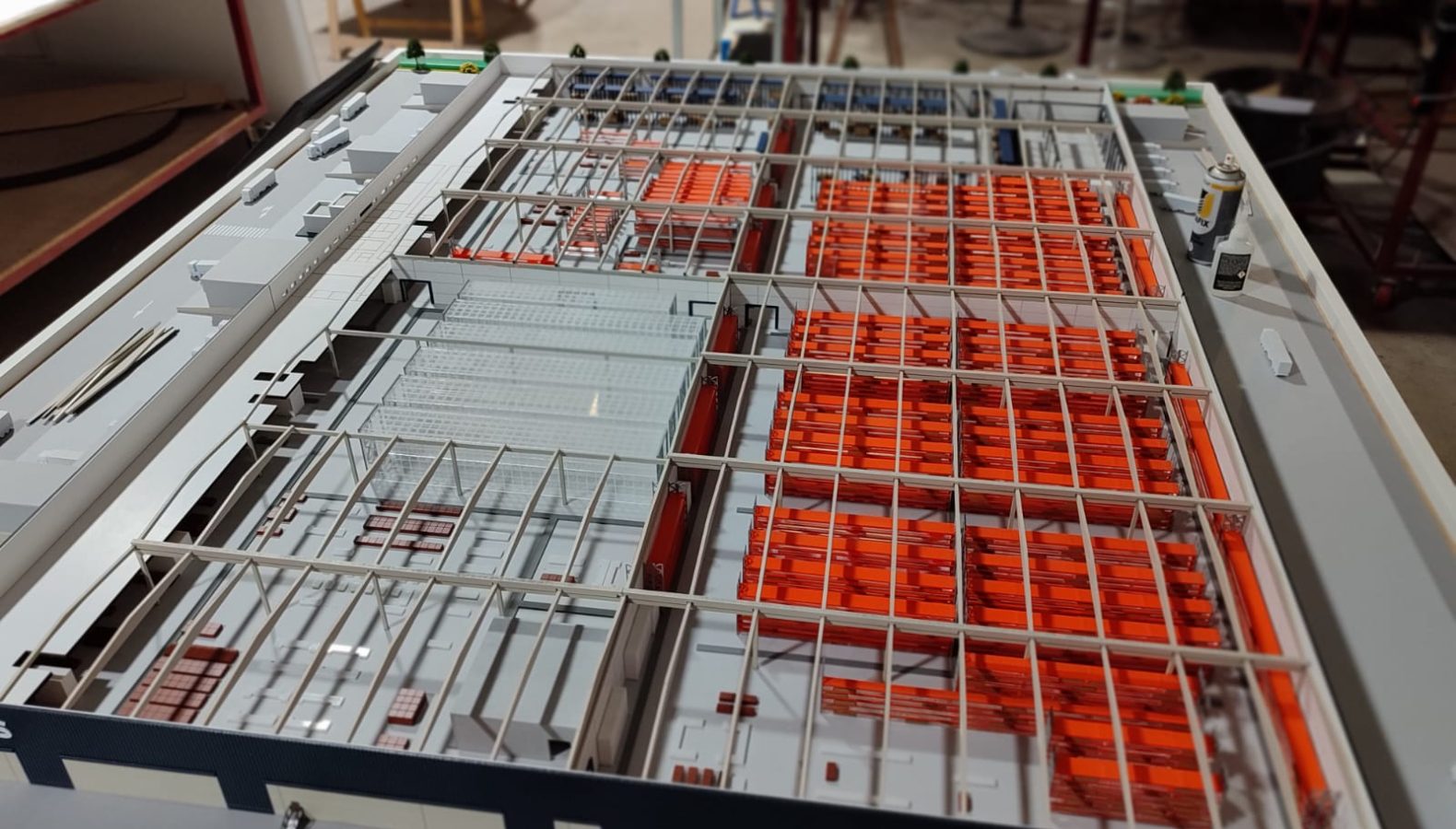

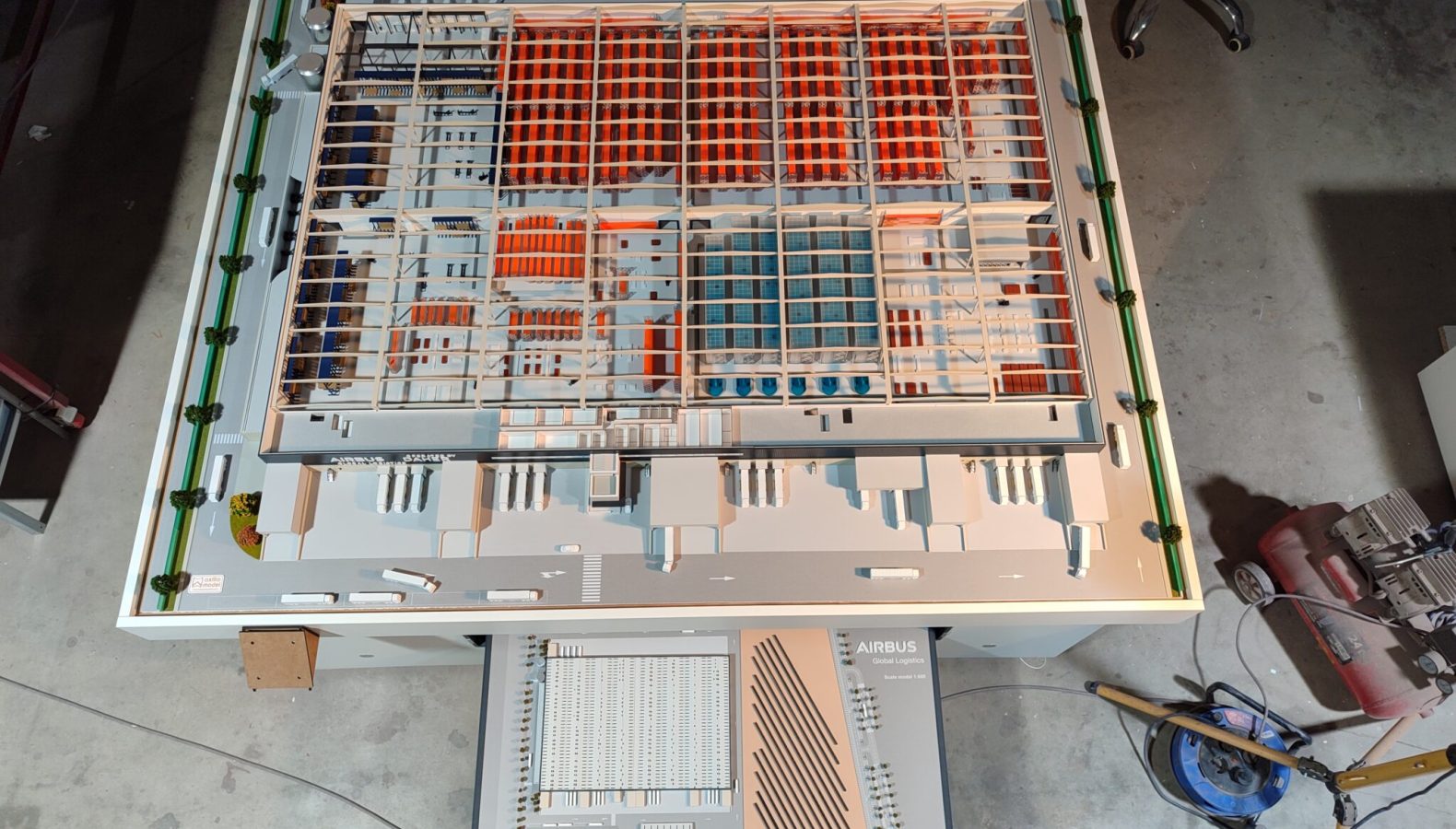

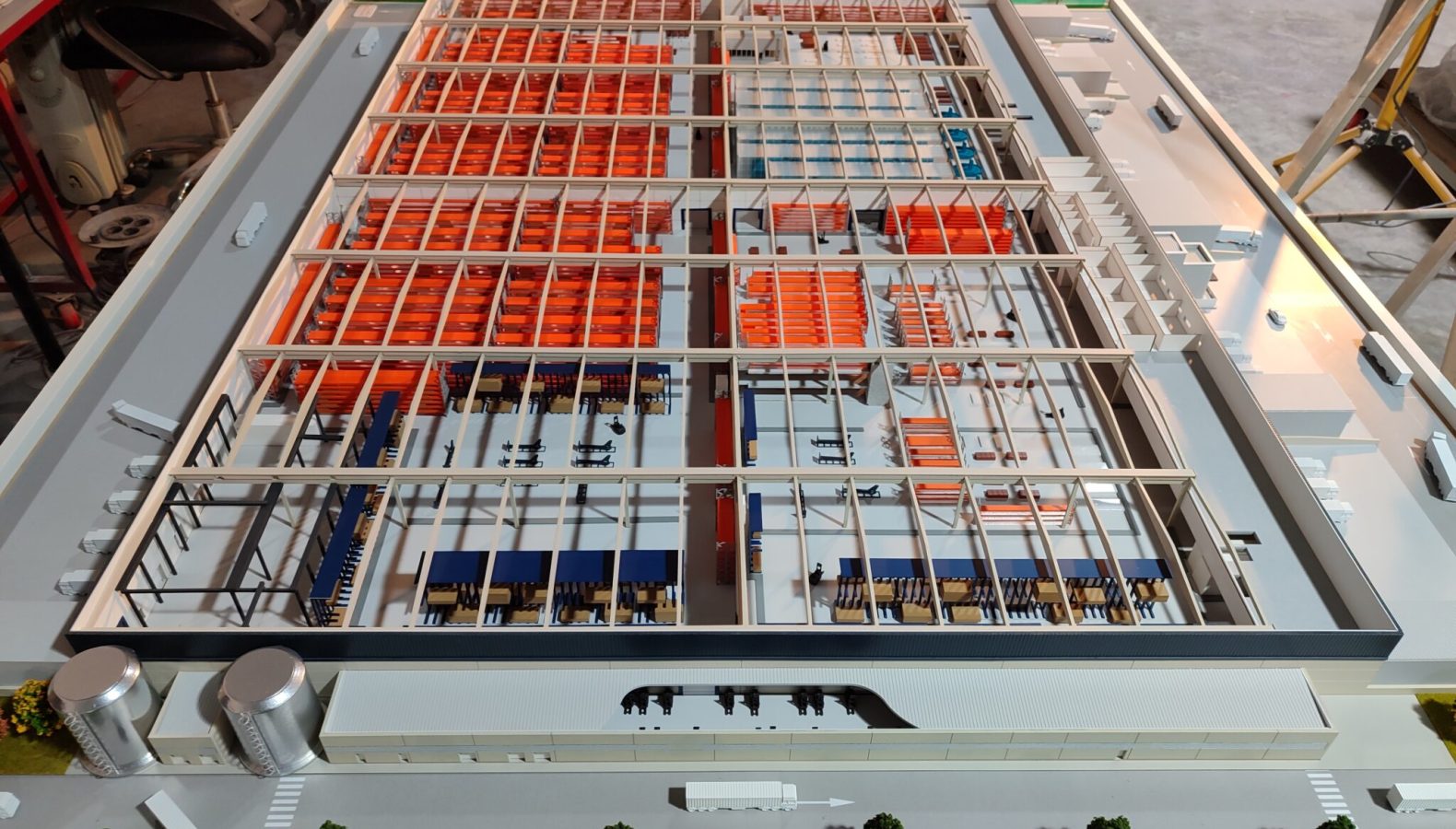

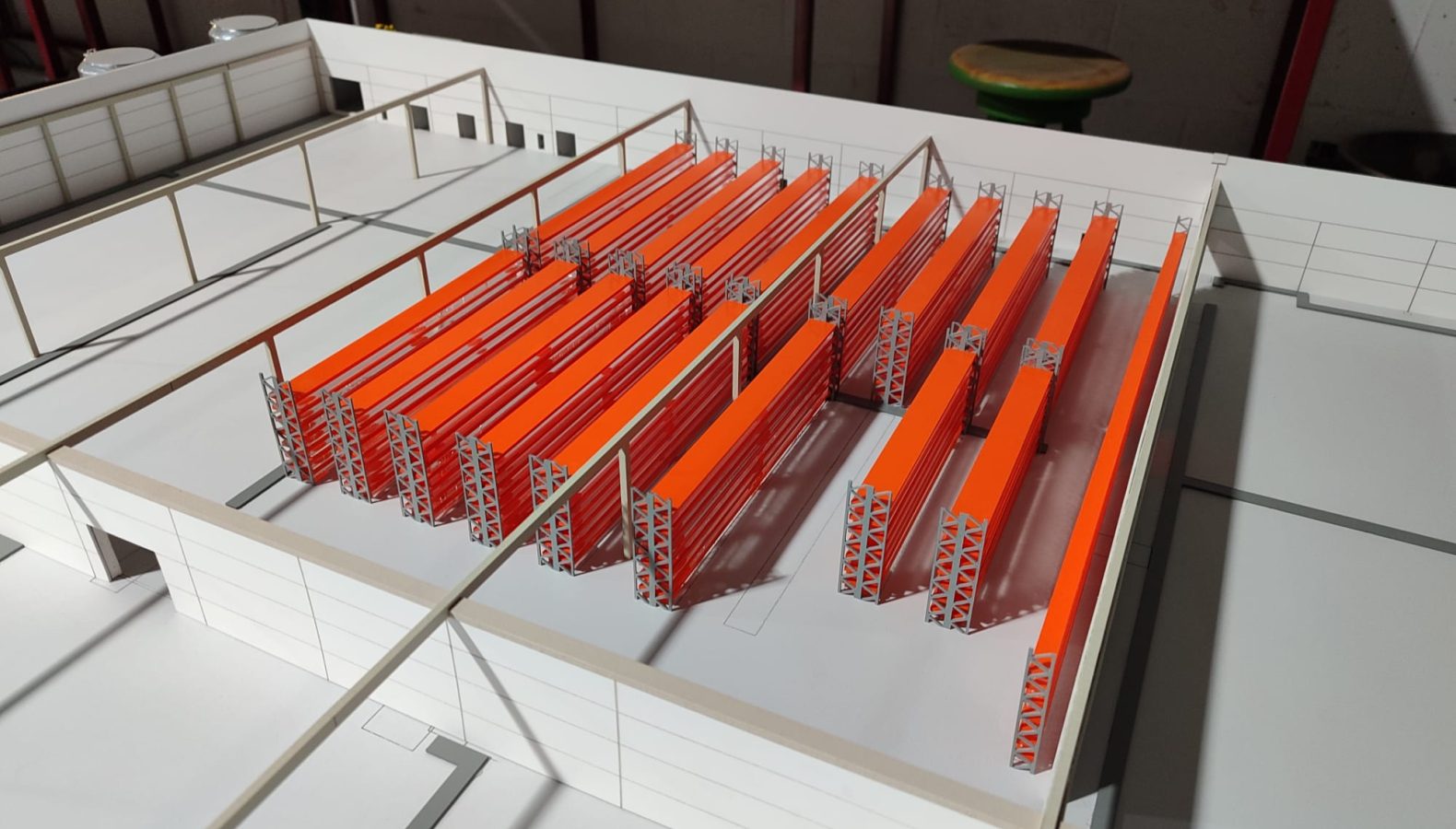

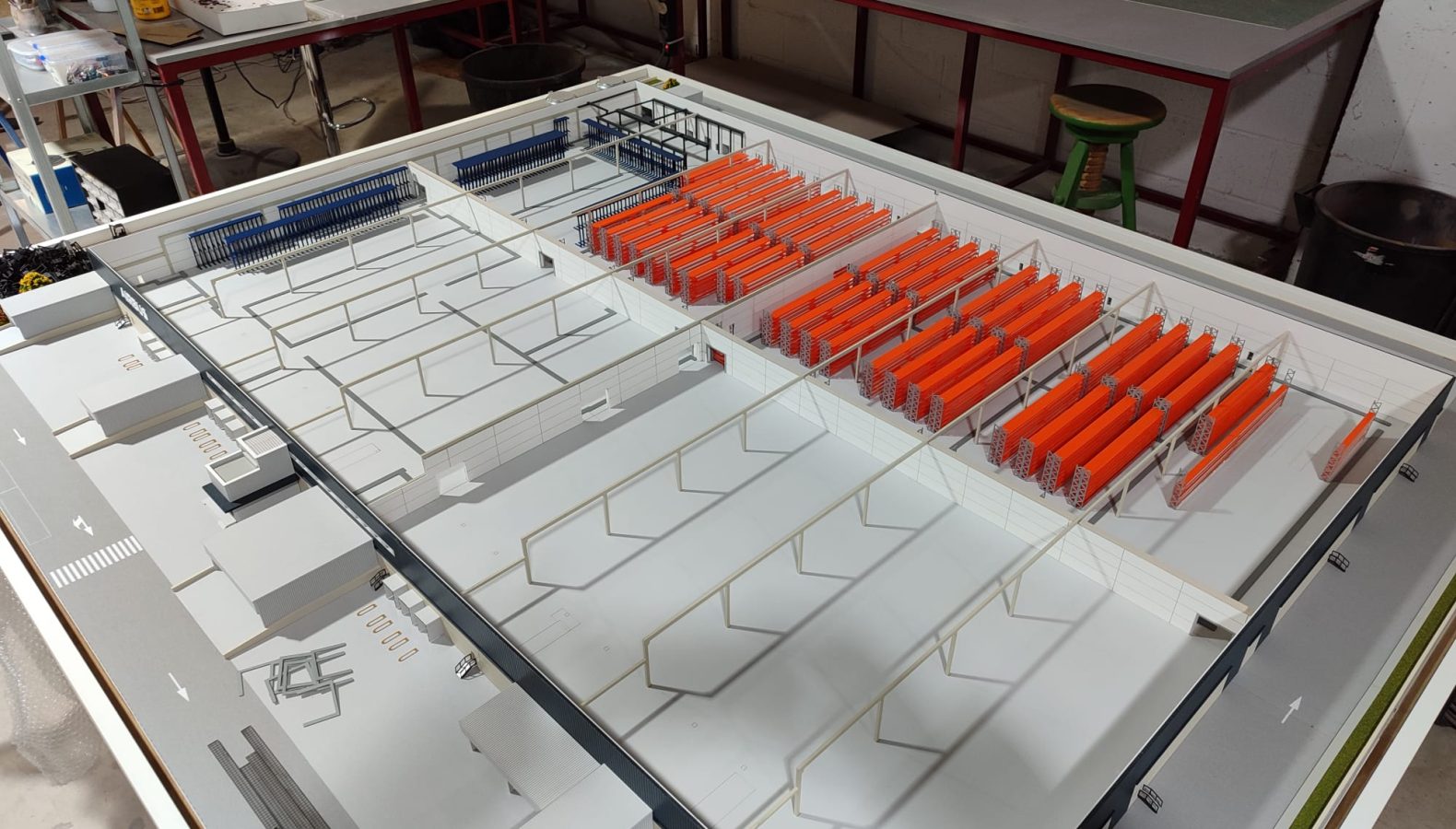

The project, which covers a total surface area of 220,000 m² and a building of 40,000 m² with a height of approximately 12 metres, stands out for its complexity and magnitude. The model developed by Savener is a realistic and detailed representation of the industrial building, including both the exterior and the interior of the facilities. Measuring 2×2 metres, this model is an essential tool for visualising and communicating the design and functionality of the building.

In addition to the main model, Savener has designed and manufactured customised display furniture, which includes an additional model on a pull-out tray in the furniture, showing the complete project on a different scale.

Savener’s team, composed of a multidisciplinary group of experts in architecture, 3D development, digital fabrication, 3D printing, model makers, fine arts, graphic design and programming, has been key to the realisation of this ambitious project. The combination of diverse skills and advanced technologies has enabled Savener to deliver a final product that not only meets the highest quality standards, but also adds significant value to Airbus’ decision-making process.

Savener’s experience in digital modelling options is vast and this time he has ventured into a new world of Physical Modelling which is very useful for prototyping and the purpose at hand. This work has increased his expertise in advanced 3D representation and includes everything from craft modelling to 3D development and 2D exploded views, the use of large format CNC machinery for engraving and cutting, the manufacture of reproductions using flexible moulds, and the application of automation technologies through programming software, robotics and electronics. This knowledge has been fundamental to create an interactive model that can be controlled through a tablet, offering an immersive and detailed experience for users.

With this project, Savener not only reaffirms its commitment to innovation and quality, but also demonstrates its ability to develop comprehensive solutions that enhance the value of its customers in strategic sectors. The Airbus Helicopters mock-up is a clear example of how collaboration between leading companies can generate results that transcend expectations and contribute to long-term success.