- Location: Hangar H1.1. Airbus San Pablo Sur Factory, Seville.

- Main data: 1.740 m2 surface area of action

- Technology: Update Hangars

- Client: Airbus Defense & Space

Savener has developed the Engineering Design and Works Management of the Adaptation of the Loading/Unloading Platform of the Beluga transport aircraft.

The Beluga (A300-600ST) super transport aircraft is used, among others and mainly, for the movement of equipment for the ISS (International Space Station) or for the transfer of components and parts of the different aircraft that are finally assembled in the FAL (Final Assembly Line) centres that Airbus has distributed all over the world, Seville being one of these.

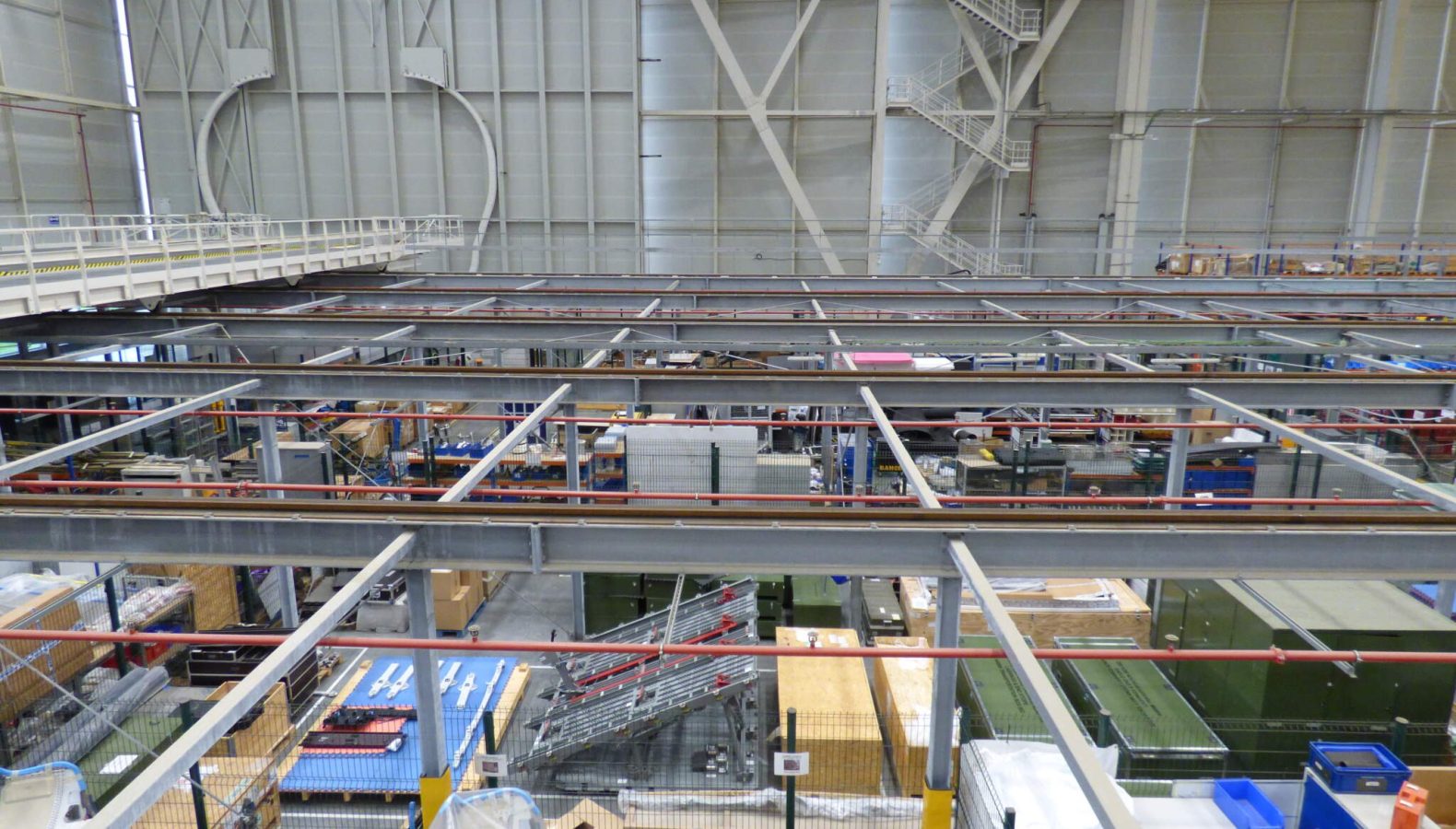

Beluga, as has been indicated, is an aircraft with a large transport capacity; it has external dimensions of 56.2 m in length, 44.8 m wingspan and a height of 17.2 m and can hold loads of up to 47 tonnes in its hold with maximum dimensions of 3.7 m in width and 37.7 m in length. One of the largest in its class. The loading/unloading platform used at the San Pablo Sur Factory (Seville) to manage the goods transfer processes is therefore an exceptional infrastructure, key to the production process and with very demanding and strict requirements to maintain.

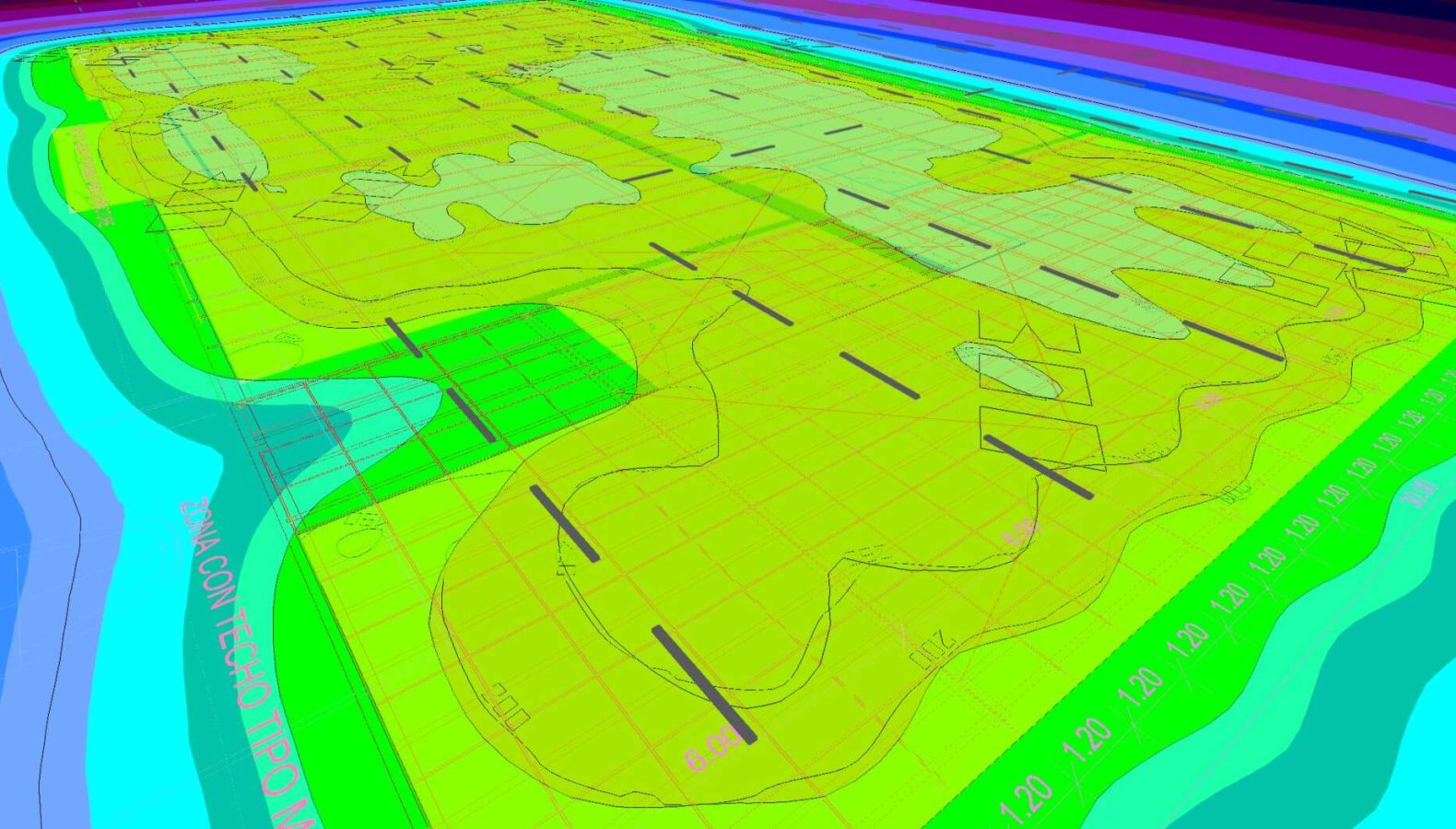

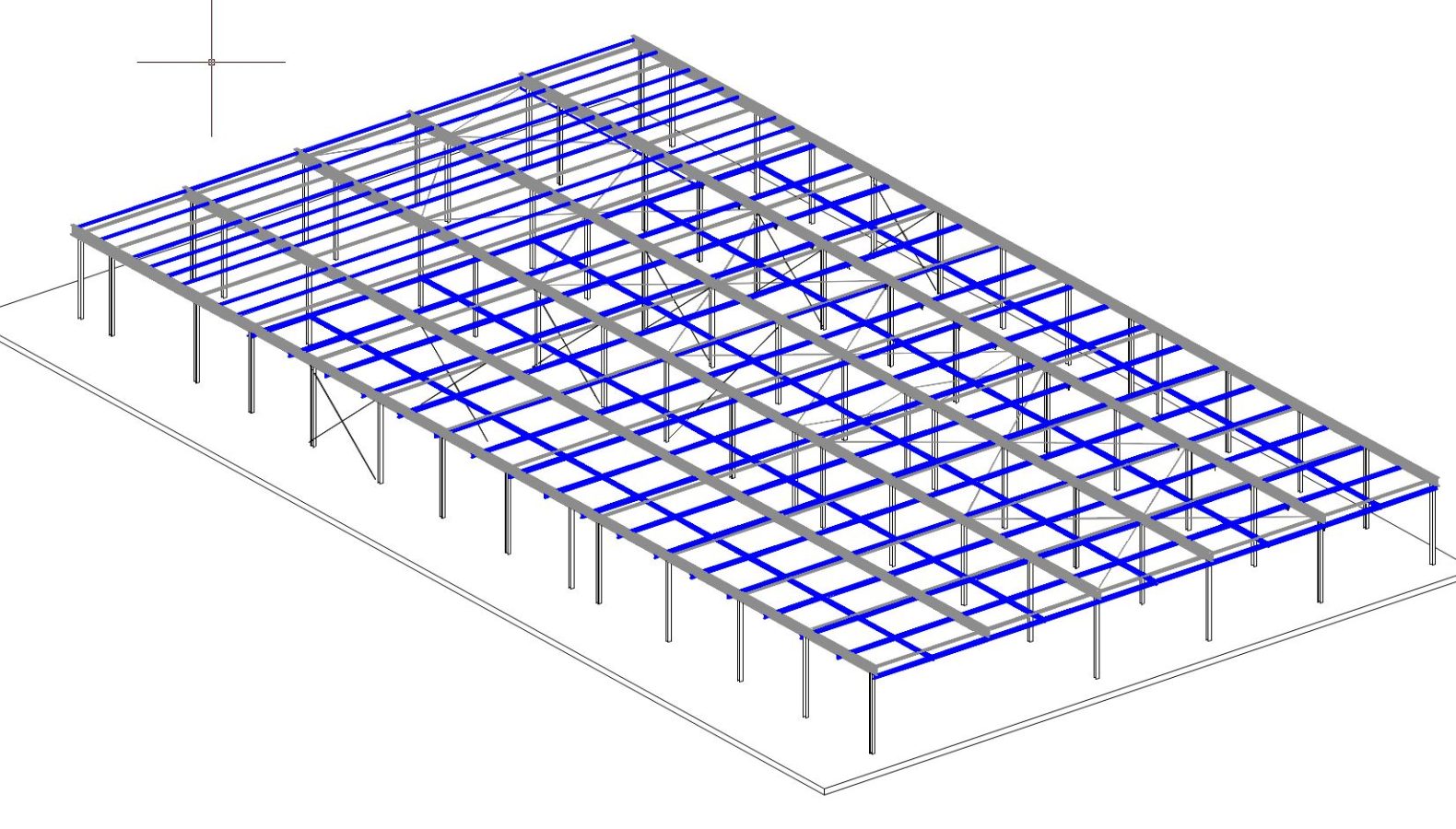

The Beluga platform of the San Pablo Sur Factory has a surface area of approximately 1,740 m2. In order to adapt the uses of the area under the Beluga service platform, it was necessary to improve the extinguishing systems, mainly consisting of an installation of 230 automatic sprinklers, installed in a fixed network of automatic extinguishing systems under load.

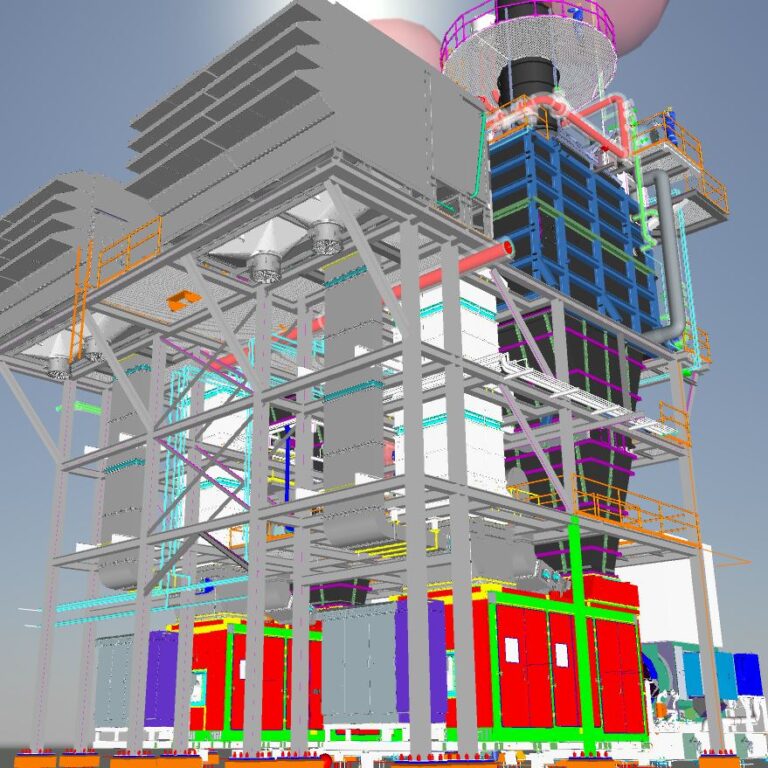

For the development of the project, the Savener team has carried out extensive and detailed data collection with the aim of being able to incorporate the state prior to the planned action in the three-dimensional models. One of the main objectives in this project was the incorporation of a horizontal separation surface to ensure the activation of the fixed automatic extinguishing systems and to separate the Beluga’s area of action from the area below. This separation surface had to comply with all regulatory requirements, both Spanish regulations (R. D. 2267/2004, UNE-EN 12845), as well as the company’s internal requirements and other international standards (NFPA-13). In addition to regulatory compliance, it has been necessary to adapt the solutions to the Platform’s operating configuration.

It was necessary to incorporate a lighting system consisting of 180 energy-efficient lighting points, adapted to the distribution of spaces under the platform, which had to be coordinated with the extinguishing system.

During the execution of the work, it was necessary to adapt to the platform’s usage rhythms in order to allow the plant to continue operating. This was achieved through controlled planning that took into account the needs of all the agents involved in the operation of the Beluga Platform.

Compliance with objectives, incorporation of extinguishing and lighting systems, regulatory requirements and maintenance of operations at the Beluga Platform have made up a new performance by the Savener team to which it has responded efficiently, offering the solvency required in exceptional cases and projects such as this one, which are more complex due to their implementation and development than to the solutions employed.