- Location: GETAFE

- Main data: Surface area: 350m²; Volume: 3200m3; Cooling load: 41KW; Heating load: 35KW

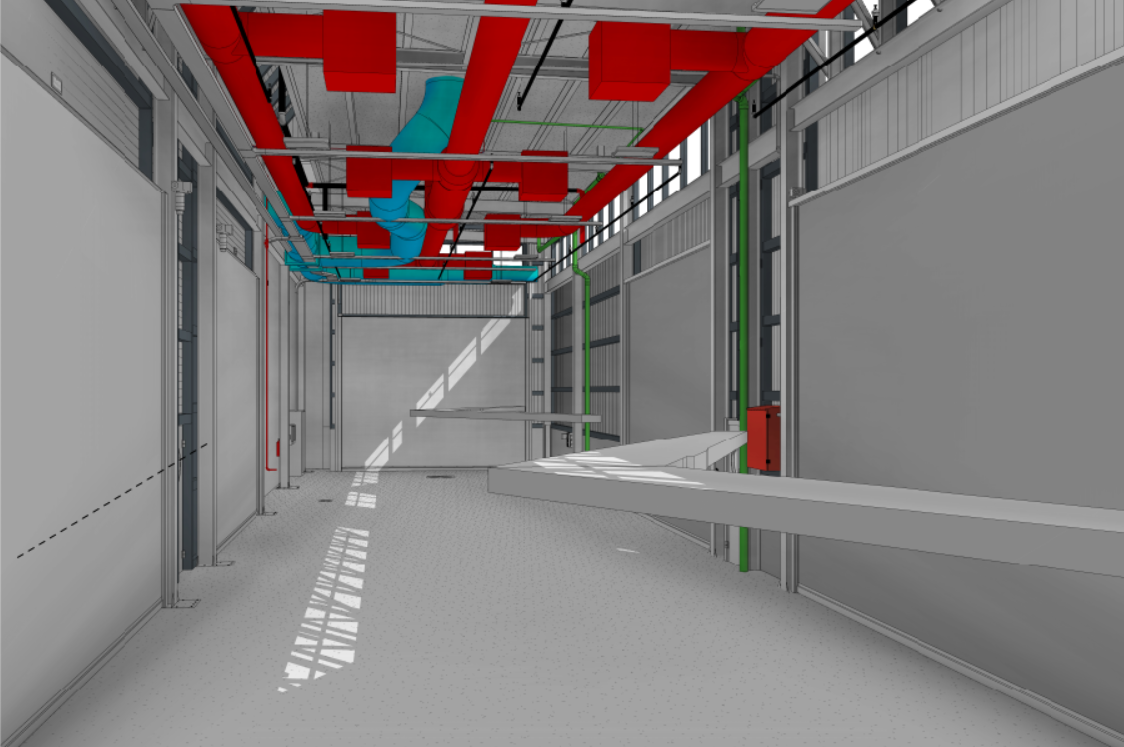

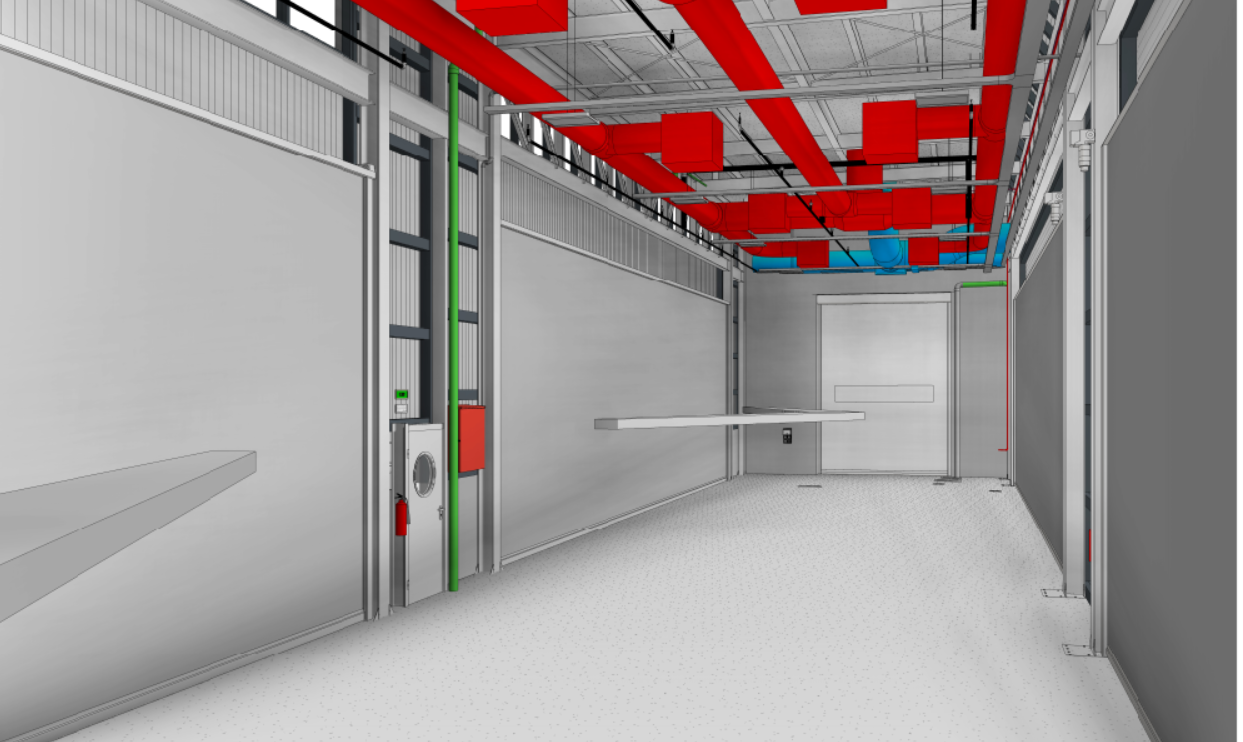

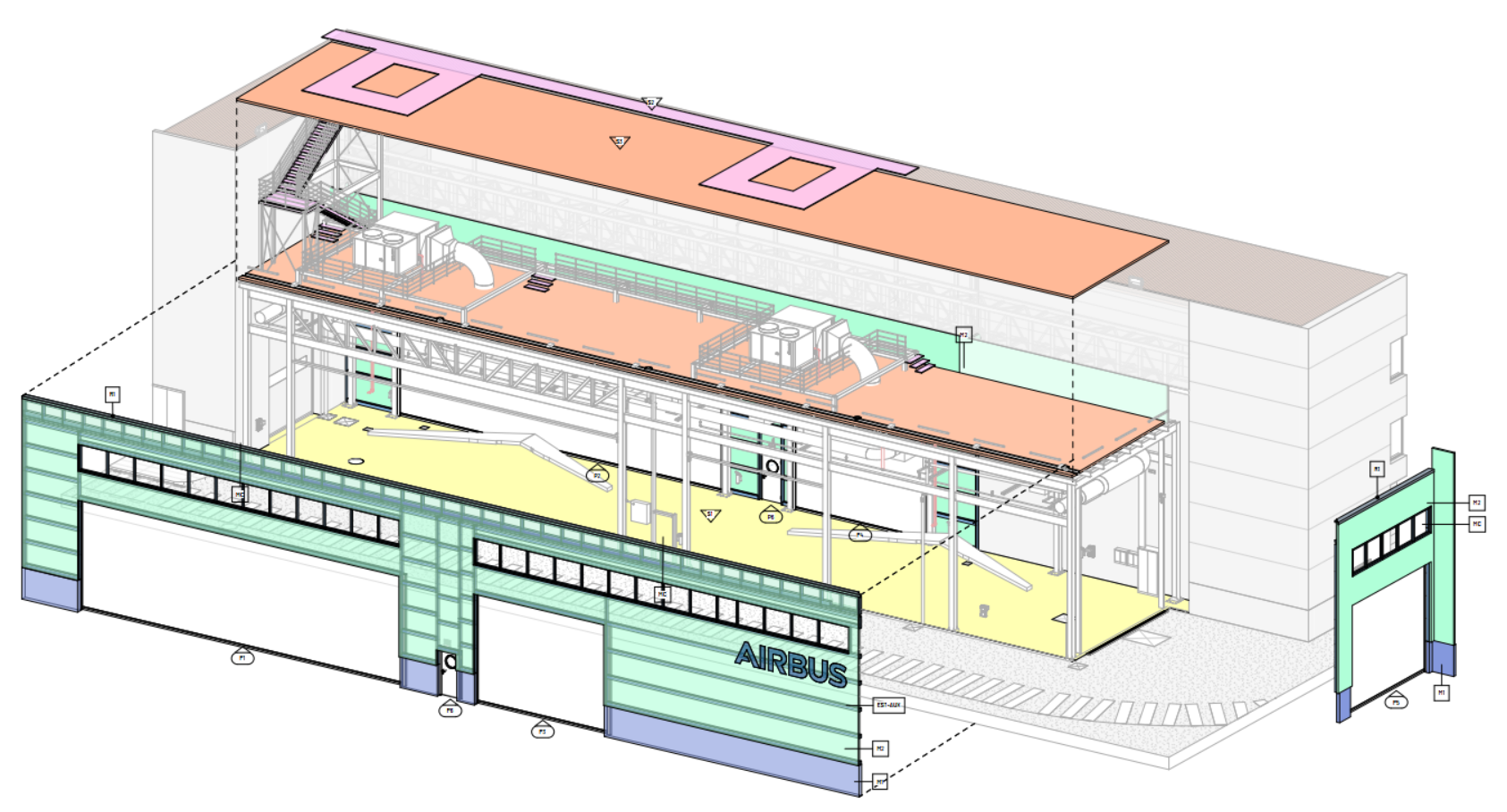

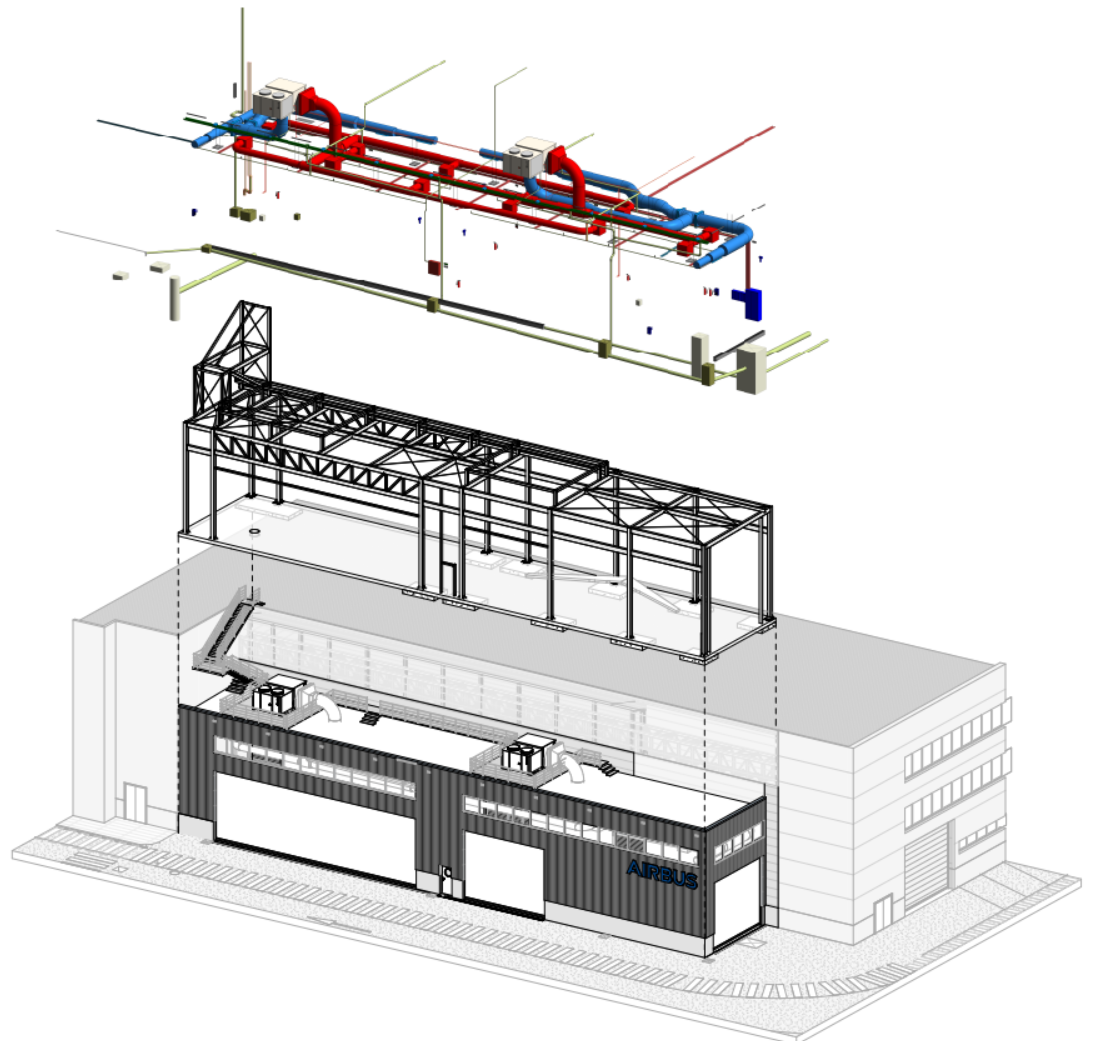

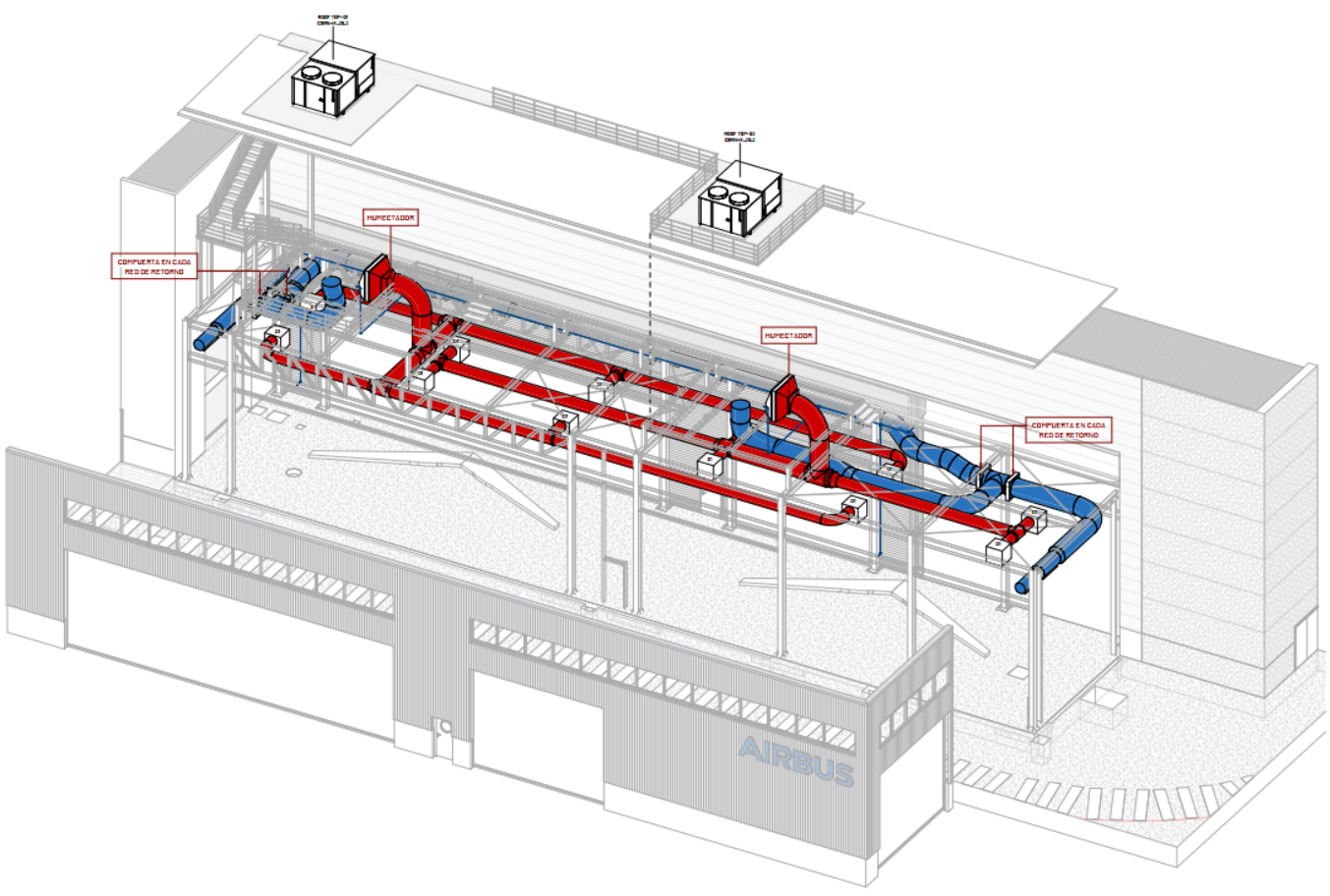

- Technology: Metallic structure with large spans saved with long trusses. Two high performance and energy efficient roof top units. Integrated LED lighting with natural lighting

- Client: AIRBUS

Savener, a benchmark engineering company, recognised for its multidisciplinary approach and commitment to innovative and sustainable solutions, has carried out an ambitious project at the Airbus Getafe factory.

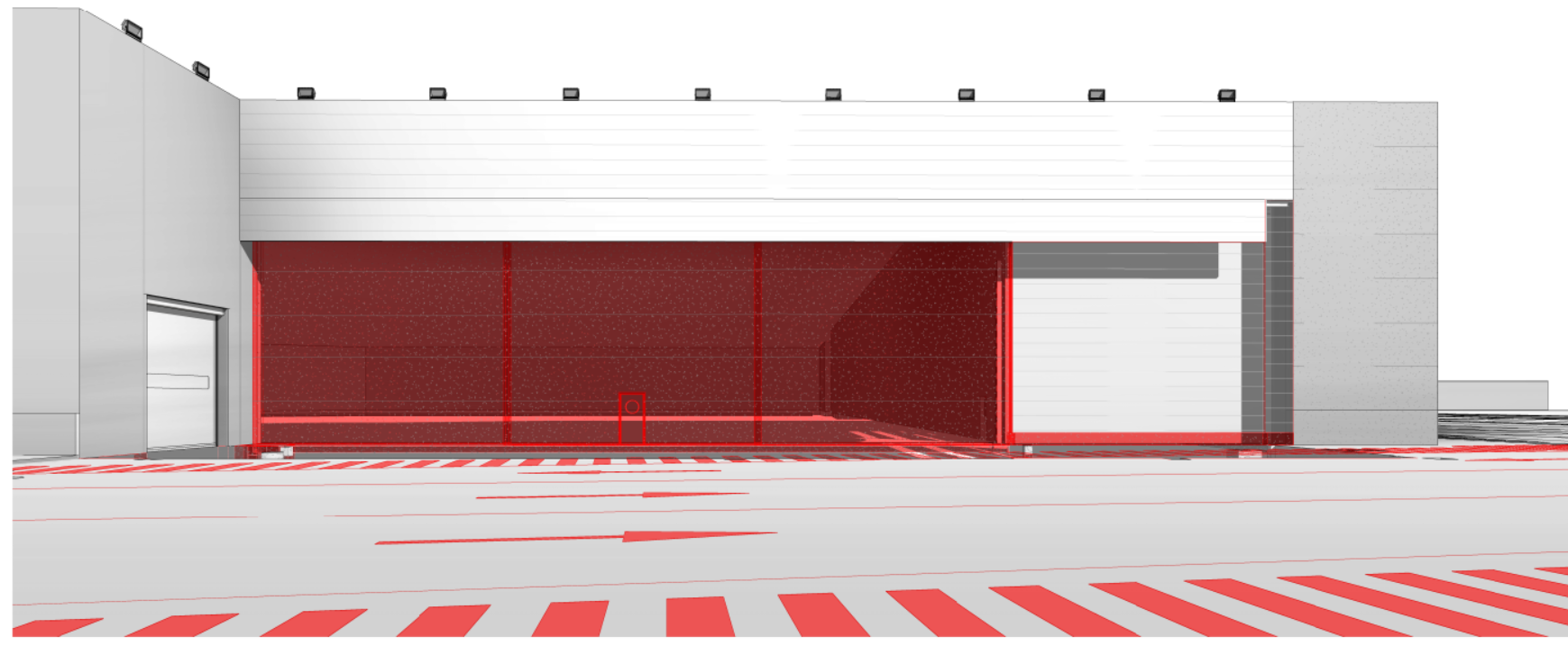

This challenge consisted of designing a building annexed to the A1 hall that would provide a system to solve the energy loss originated through the gates, once opened due to the entry of tools and aeronautical materials into the A1 hangar, essential infrastructure for the A320 production line.

Aware of the demands of the industrial environment and the strict deadlines managed by the client, Savener has designed an airlock building attached to the hangar which, in addition to resolving energy losses, maintaining humidity and temperature conditions, improves operational flows.

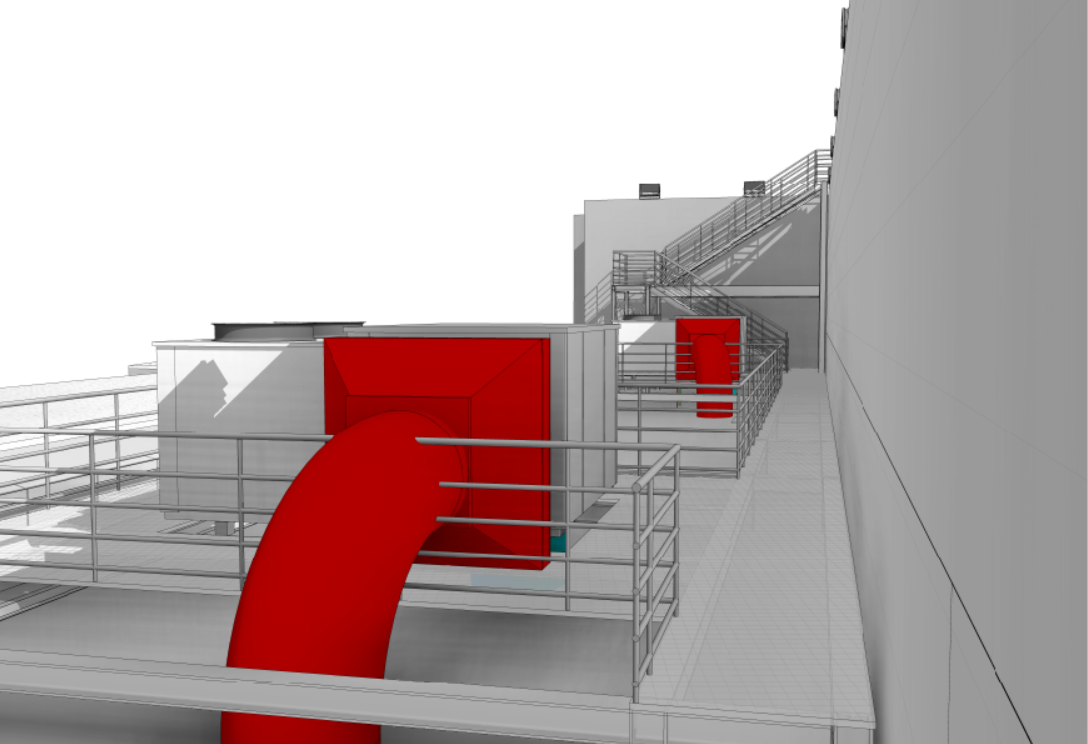

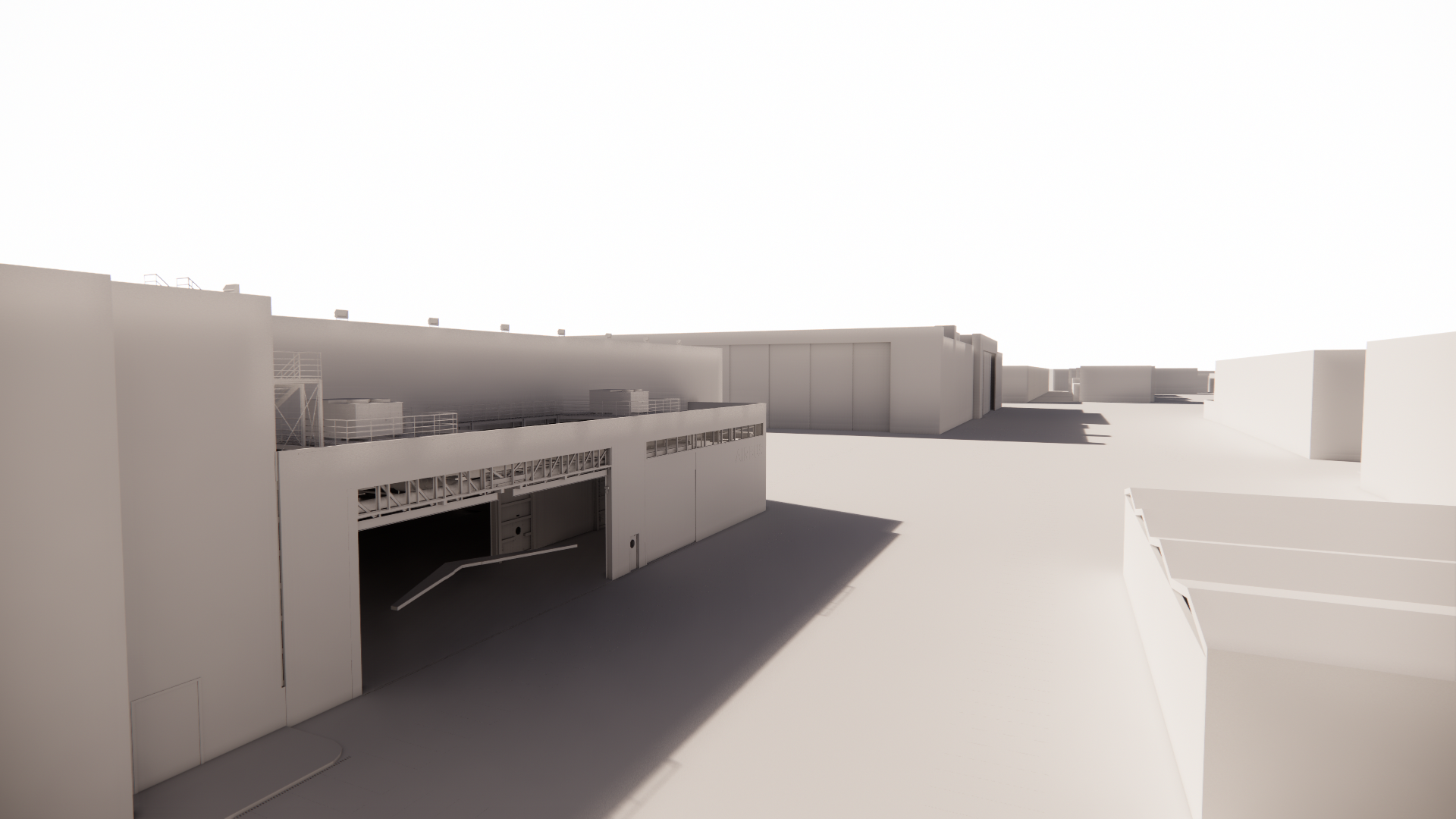

The project has been developed with a meticulous and detailed 3D model, which not only shows the continuity of production, but also expands the operational possibilities, improving the circulation flows of operators and production parts and contributes to a more efficient and sustainable environment.

The project stands out for the integration of the BIM methodology from the initial phases, being a key tool in the process of the projects designed by Savener, from design to execution, since after the project it forms an important part of the project management in the construction process. The model was complemented with advanced thermal and lighting simulations, which made it possible to predict the behaviour of the system in different scenarios, and with a three-dimensional point cloud survey of the intervention area. These techniques ensured an accurate virtual model, minimising any possible deviations in the work and adjusting the budget; trying to avoid deviations and integrating the new building in the tight initial conditions.

Savener’s ability to execute a project of this level of complexity in a reduced timeframe was essential to meet the deadlines imposed by Airbus. The A320 production line, due to its strategic nature, could not be stopped, which required the development of fast, effective and seamlessly integrated solutions within the industrial environment.

In addition to solving the customer’s immediate needs, this project brings significant added value by including the possibility to develop the 3D model as a future digital twin of the physical system to help monitor conditions and savings. This provides Airbus with a key tool for the future, allowing it to integrate this infrastructure into predictive maintenance and operational optimisation strategies. The anticipation of potential failures and the ability to make informed decisions thus become competitive advantages for the factory.

The approach taken by Savener focused not only on functionality and on-time delivery, but also on sustainability and integration with the industrial environment. The design incorporates energy efficient systems and solutions that reduce environmental impact, reaffirming the company’s commitment to responsible development aligned with sustainability objectives.

In this project, Savener once again demonstrates its ability to tackle complex challenges, offering solutions that combine innovation, technical precision and sustainability. This approach, focused on maximising customer value and ensuring long-term functionality, positions Savener as a benchmark in advanced industrial projects.