- Location: Airbus San Pablo Sur Factory. Seville

- Main Data: Refurbishment of the roof of Warehouse H1.1, H1.2, H2, H2, H3, C2 and Logistic Dock. Approximate area: 91.000m². 100% waterproofing refurbishment. 20% renovation of insulation.

- Technology: Waterproofing; insulation; Danosa; technical corridors; improvement in infrastructures and maintenance.

- Client: AIRBUS

Savener, as a reference engineering company for Airbus, has led the reform of the roofs of the hangars in the factory of San Pablo Sur, Seville. This project has been a technical and logistical challenge, addressed with precision through a detailed study of the existing pathologies and the application of innovative solutions in waterproofing, energy efficiency and structural safety.

A precise diagnosis for an effective solution

The condition of the hangar roofs prior to the intervention showed significant deterioration. Deficiencies in the waterproofing, water accumulation in critical areas and leakage problems were identified that compromised the durability of the envelope system. Through detailed inspections and specialised testing, the key points to be corrected were defined, ensuring that the refurbishment was carried out with sound technical criteria and high performance solutions.

Solutions applied: innovation in waterproofing and energy efficiency

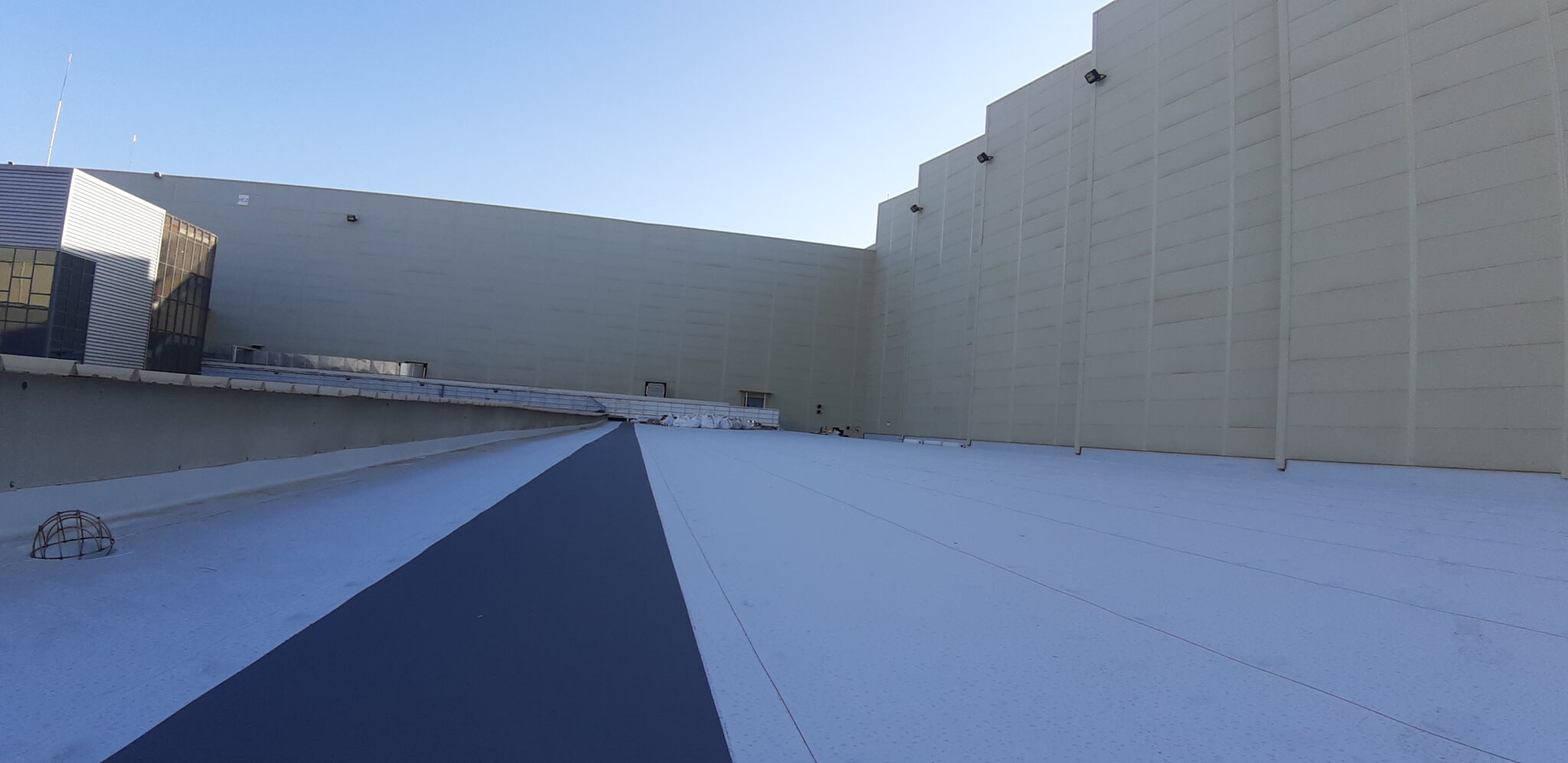

The project involved the application of a new waterproofing system based on high-strength PVC sheets, guaranteeing a useful life of at least 20 years and providing watertightness in extreme weather conditions. To avoid incompatibilities with the pre-existing system, a geotextile separation layer has been implemented, protecting the new membrane and ensuring its durability.

In the areas with the greatest accumulations of water, such as sinkholes and gullies, the deteriorated layers of insulation have been replaced with rigid rock wool panels, the slope has been slightly modified at conflictive points by installing galvanised steel sheets on omega profiles under the insulation, optimising the water evacuation levels and preventing future filtrations; redirecting the flow of water towards the sinkholes with greater efficiency.

Infrastructure and safety improvements

To ensure the safety of maintenance personnel and the integrity of the waterproofing system, anti-slip technical walkways have been installed, allowing safe passage without affecting the roof. In addition, the fixing of the sheeting has been reinforced at critical points by means of mechanical plates, ensuring its stability in variable wind and temperature conditions.

Fixed self-supporting handrails have been implemented, eliminating the need for temporary nets and providing permanent fall protection. Access between different levels has also been improved with the installation of new prefabricated stairs and steps, minimising risks and ensuring the comfort of staff during maintenance work.

In terms of operational efficiency, a flushing system with water points has been implemented to facilitate cleaning and watertightness checks. Likewise, the cable routing in the lunettes has been optimised, avoiding improvised fixings that could compromise the waterproofing.

The refurbishment of the hangar roofs in San Pablo Sur responds to AIRBUS’ commitment to sustainability and its commitment to Savener as its partner. The selection of low environmental impact materials and the optimisation of energy consumption in the building reinforce the company’s global strategy in terms of energy efficiency and emissions reduction.

In addition to the technical and functional improvement, the intervention has contributed to the aesthetics of the industrial complex, ensuring a renewed and modern image of the infrastructure.

Towards the future: predictive maintenance and continuous optimization

Savener has proposed the implementation of a predictive maintenance plan to guarantee the durability of the improvements implemented. Periodic inspections, revisions of joints and seals, as well as the optimisation of water evacuation systems, will be essential to preserve the integrity of the roof in the coming years.

With this refurbishment, Savener reaffirms its commitment to excellence in industrial engineering, offering innovative and efficient solutions for the modernisation of critical infrastructures in the aeronautical industry. The optimisation of the roofs of the AIRBUS hangars in San Pablo Sur not only strengthens the operability of the factory but also sets a precedent in the strategy of renovation of facilities at a global level.