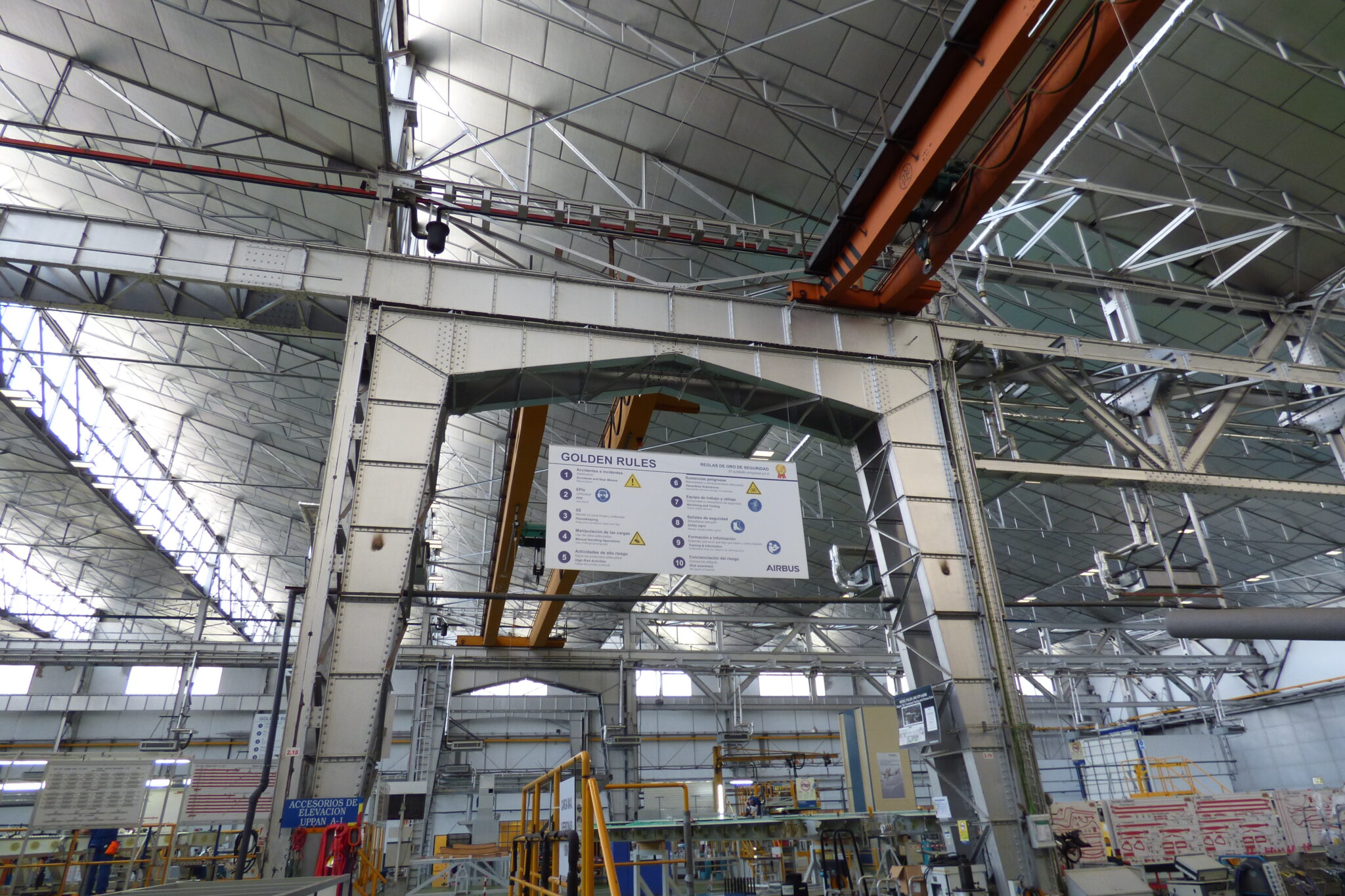

- Location: Airbus Tablada Factory. C. Hispano Aviación, 4, 41011 Seville

- Main data: 1.8 MW cooling, 2.1 MW heating, 92 fan-coil units, 13,500 m3 building, hydraulic network of more than 2,500 linear metres of piping.

- Technology: HVAC

- Customer: Airbus Defense & Space

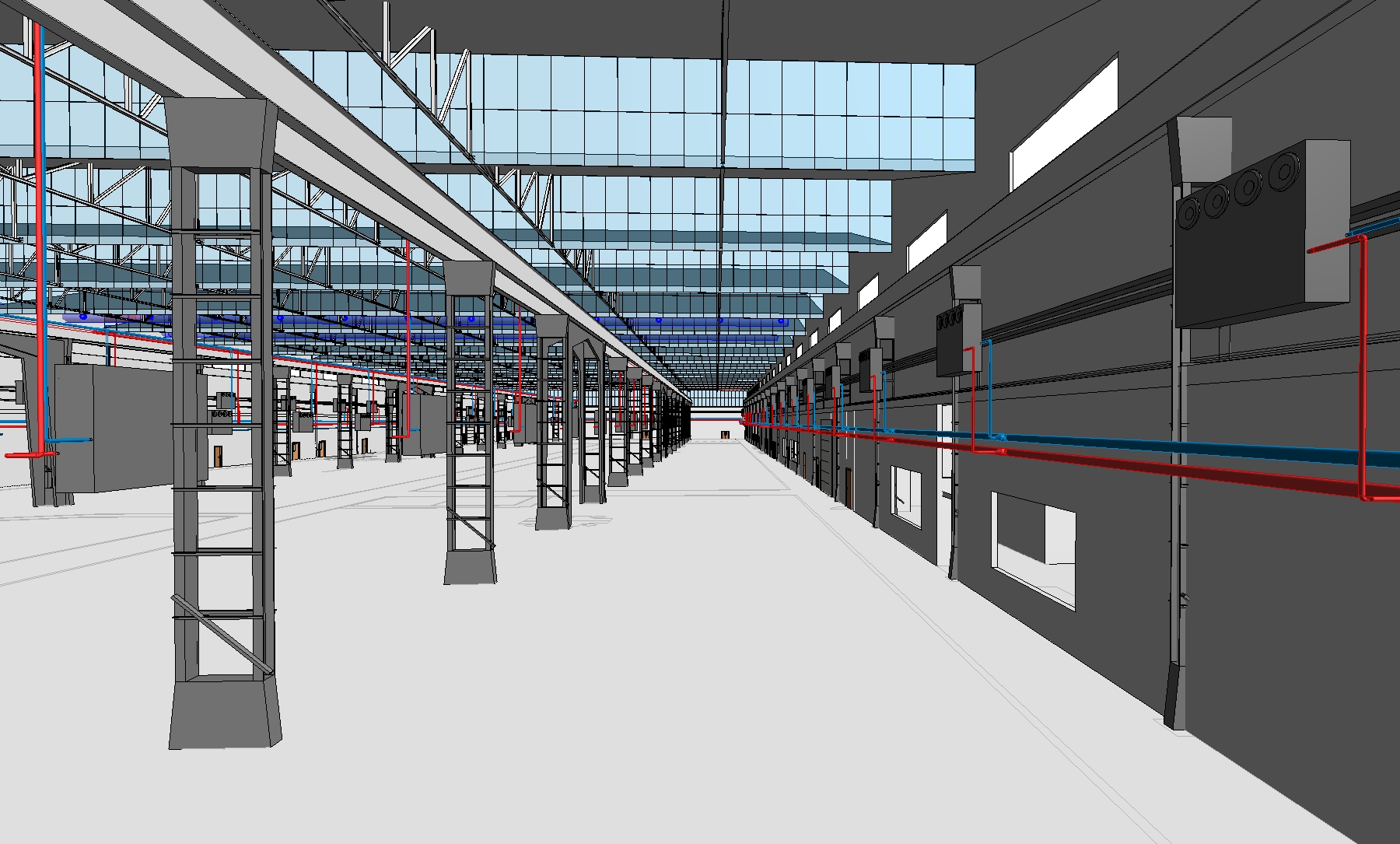

Phase III of the reform of the air conditioning system (HVAC) of the Airbus Tablada factory culminates the process of updating and modernisation of these systems that began in 2013. A strategic project that has completely transformed the plant’s energy infrastructures.

This new phase, focused on hall A, has involved the complete replacement of the hydraulic network and the air conditioning terminal units, implementing a more efficient infrastructure adapted to current requirements. As in the previous phases, the intervention required extremely precise planning and execution, maintaining active production at all times and ensuring minimum interference with daily operations.

A track record of success: Previous phases

The modernisation process at the Tablada factory began with Phase I, which involved the refurbishment of the Cold Generation Plant in Building K. During this stage, the old, highly obsolete installation was replaced by a new chilled water plant with magnetic levitation chiller plants (https://www.savener.es/en/proyectos/district-cooling-airbus-stage-1/).

In Phase II, Savener extended the cooling plant and built a new heating plant. An energy distribution ring was also installed to supply the different halls of the plant and the renovation of the interior air-conditioning installations in halls E and J was carried out (https://www.savener.es/en/news/savener-ha-completado-con-exito-y-en-tiempo-record-la-reforma-de-la-instalacion-de-hvac-en-la-nave-e-de-la-planta-de-airbus-en-tablada/)

Phase III: Innovation, technology and efficiency

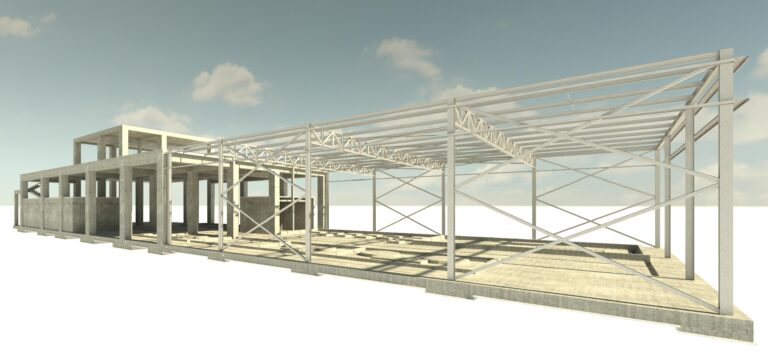

The recently completed Phase III, focused on Hall A, continues the line of modernisation implemented in the previous phases. The works have included:

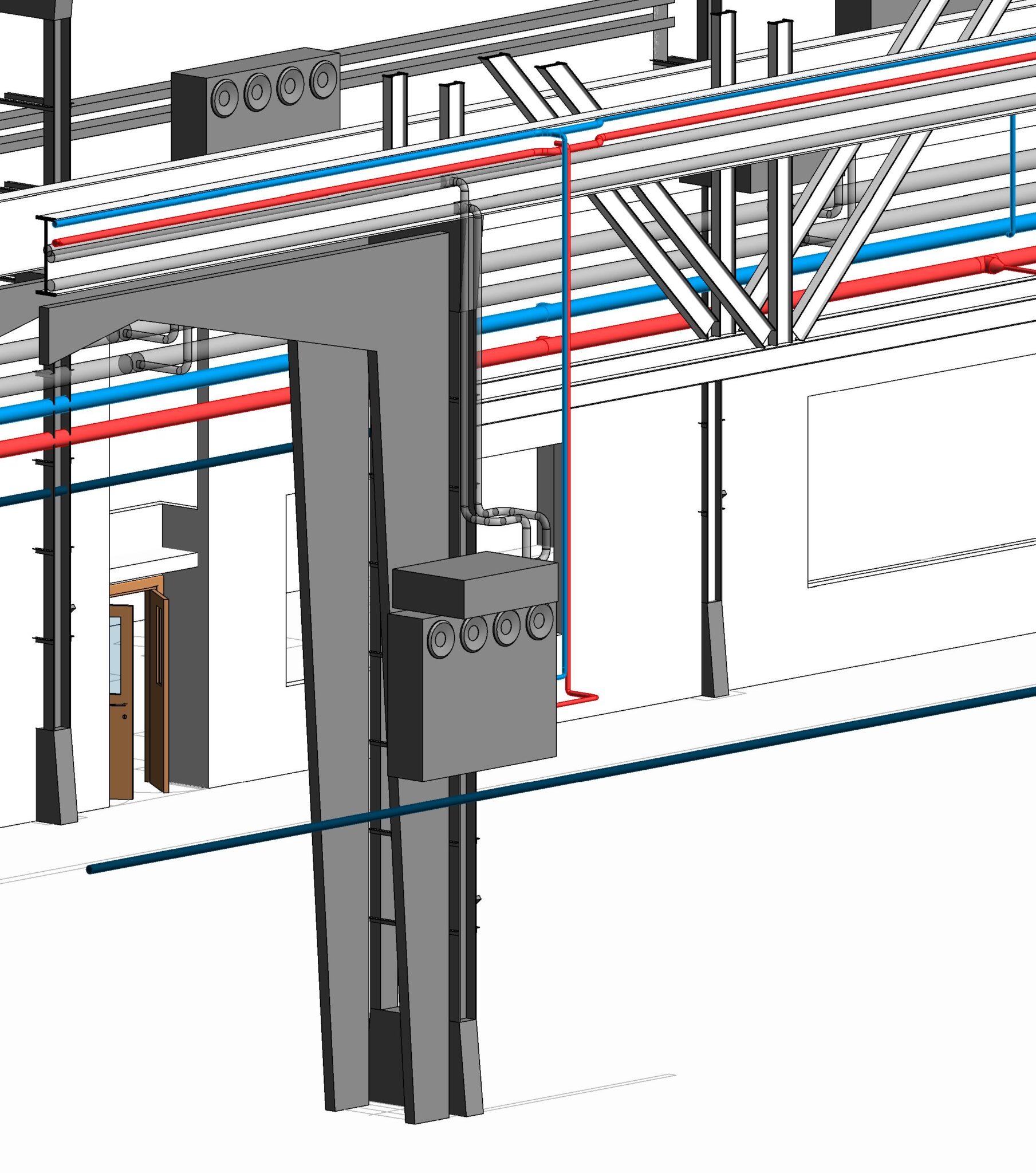

- Replacement of the hydraulic network with a new infrastructure of greater capacity and efficiency.

- Installation of variable flow air-conditioning terminal units, optimising energy consumption.

- Implementation of advanced technologies, such as magnetic levitation cooling generation, modulating condensing boilers, EC fans and BMS monitoring and control systems.

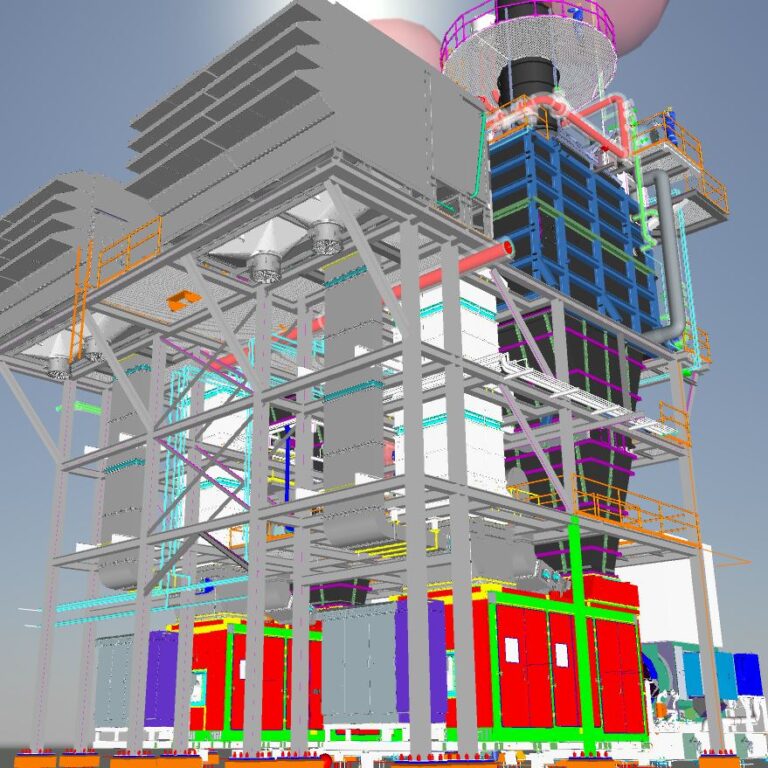

One of the most outstanding challenges has been the integration of the new infrastructure into the existing building, a common challenge in refurbishment projects where the old facilities must remain operational during execution. For this, Savener used the most advanced BIM modelling techniques. A 3D laser scan was performed to generate a point cloud of the building, facilitating accurate visualisation and seamless integration of the new systems.

A benchmark for efficiency in the industrial sector.

With the completion of this project, the Airbus Tablada factory is positioned as one of the most efficient facilities in heat and cold generation, both within Airbus and in the industrial sector as a whole in Spain. This success reflects the commitment of Airbus and Savener to innovation, sustainability and technical excellence.

Savener, as a trusted technology partner, reaffirms its commitment to continuous improvement and the development of cutting-edge and sustainable solutions that enable our customers to optimise their infrastructures and achieve the highest standards of energy efficiency.