- Location: Salalah, Dhofar Governorate, Oman

- Capacity: 113,650 m3/day

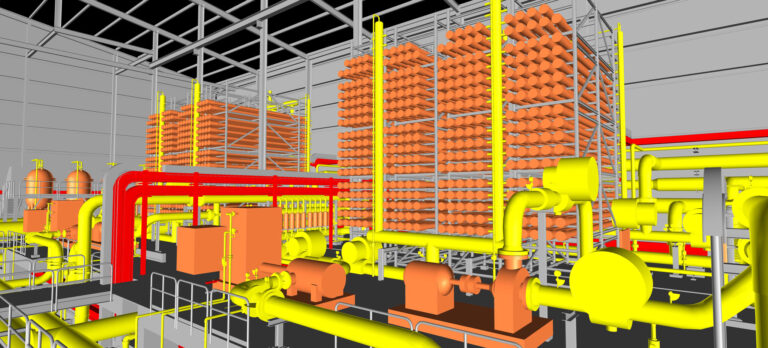

- Technology: Reverse osmosis sea water desalination

- Clients: Acwa Power, Veolia and Dhofar International for Investment and Development

- Offtaker: Oman Power and Water Procurement Company

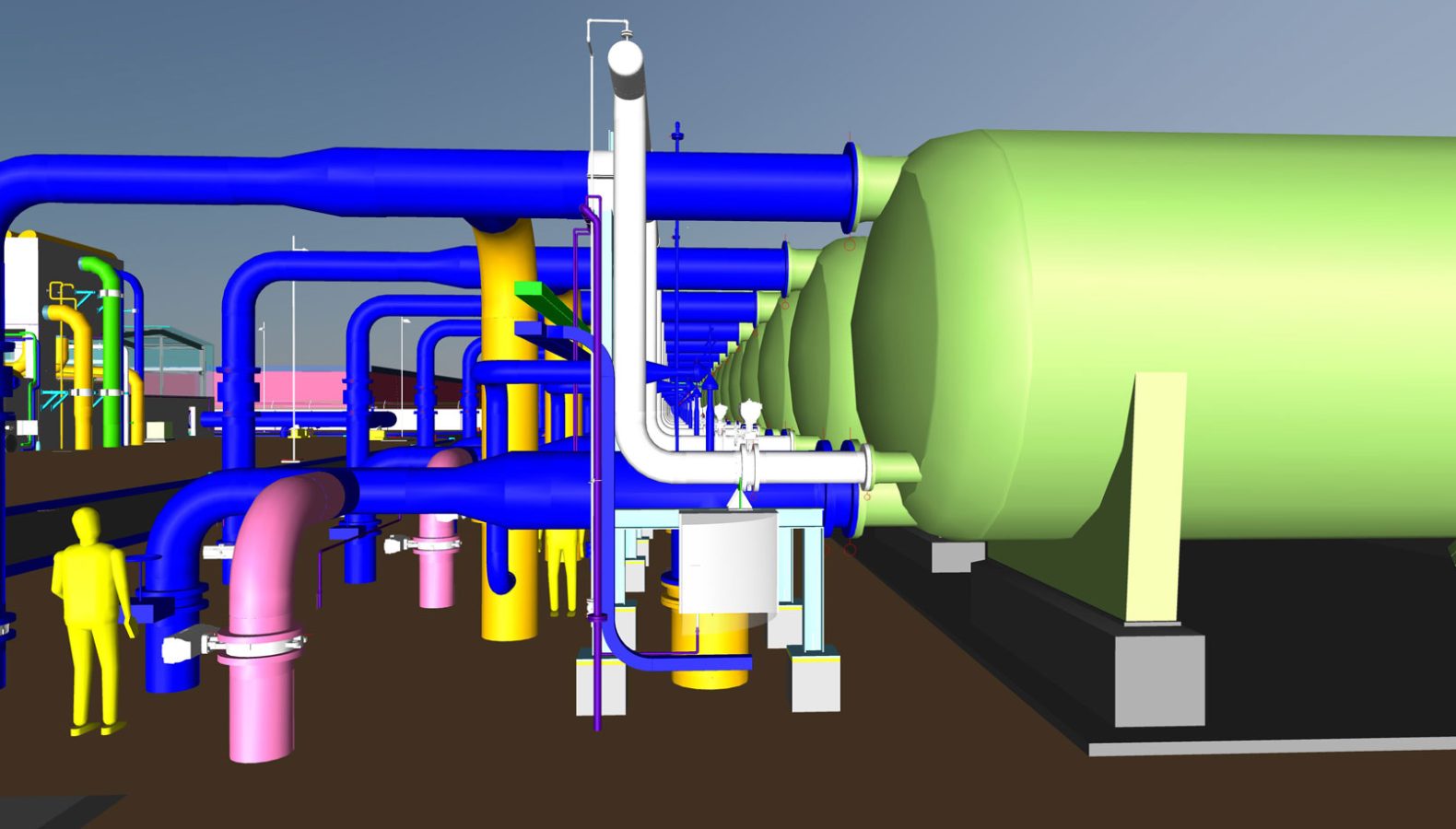

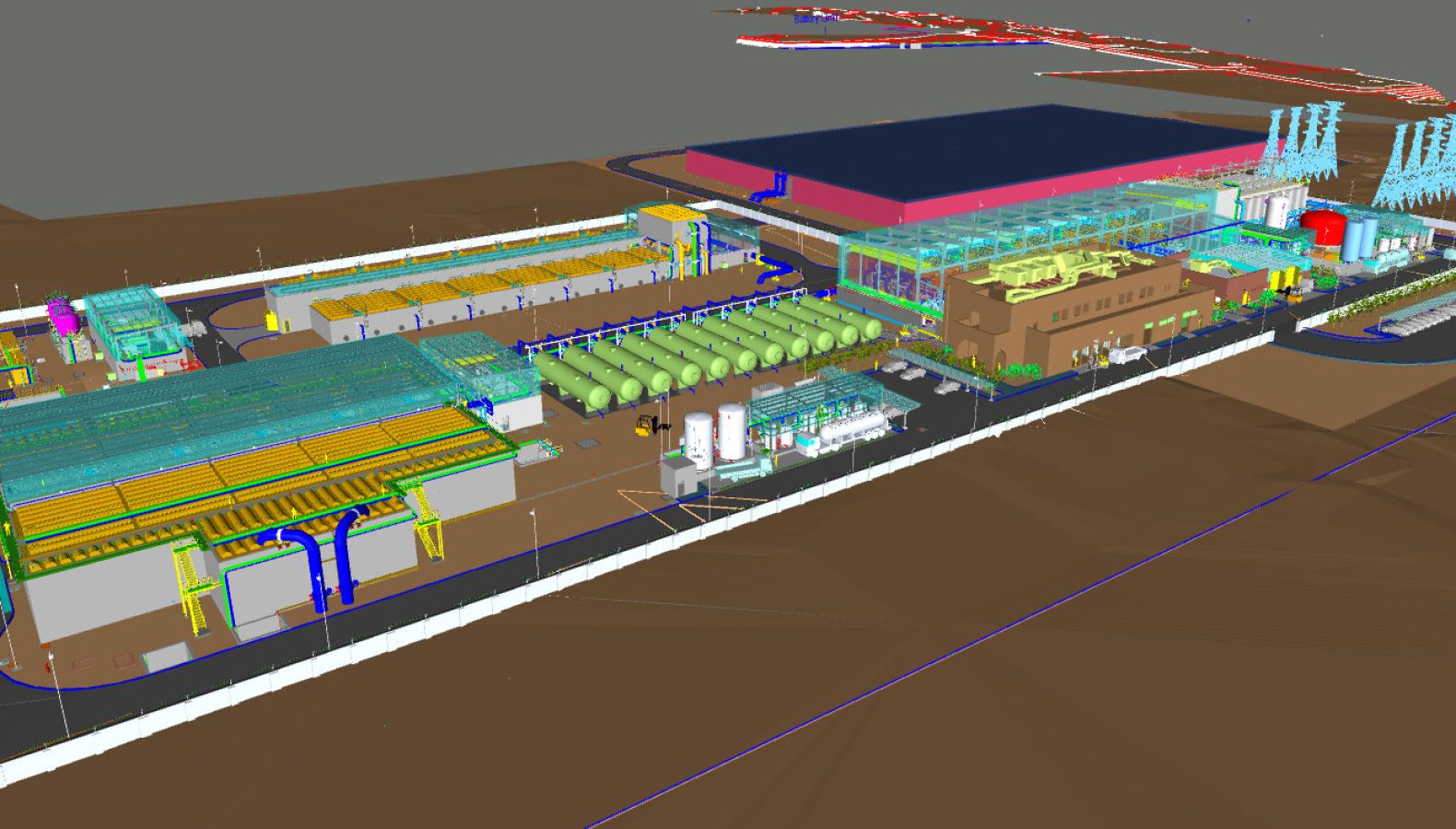

This project was developed jointly as an EPC partner with Abengoa and Fisia Italimpianti. Both participated in the different phases of Engineering, Purchasing, Construction and Commissioning of the complex.

SAVENER was selected by ABENGOA to handle various aspects of the engineering works for this Desalination Plant in the Dhofar region of Salalah, Oman

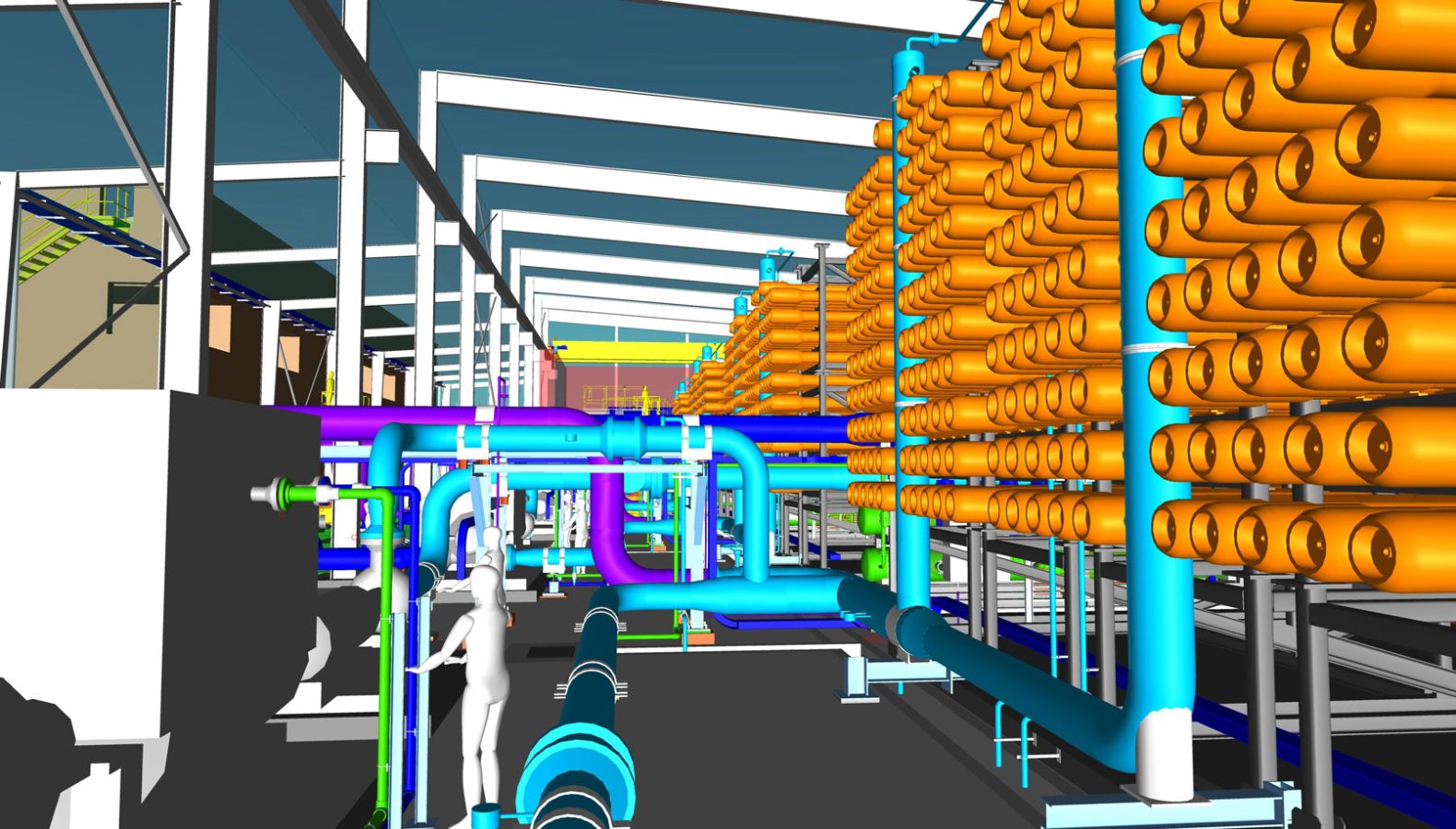

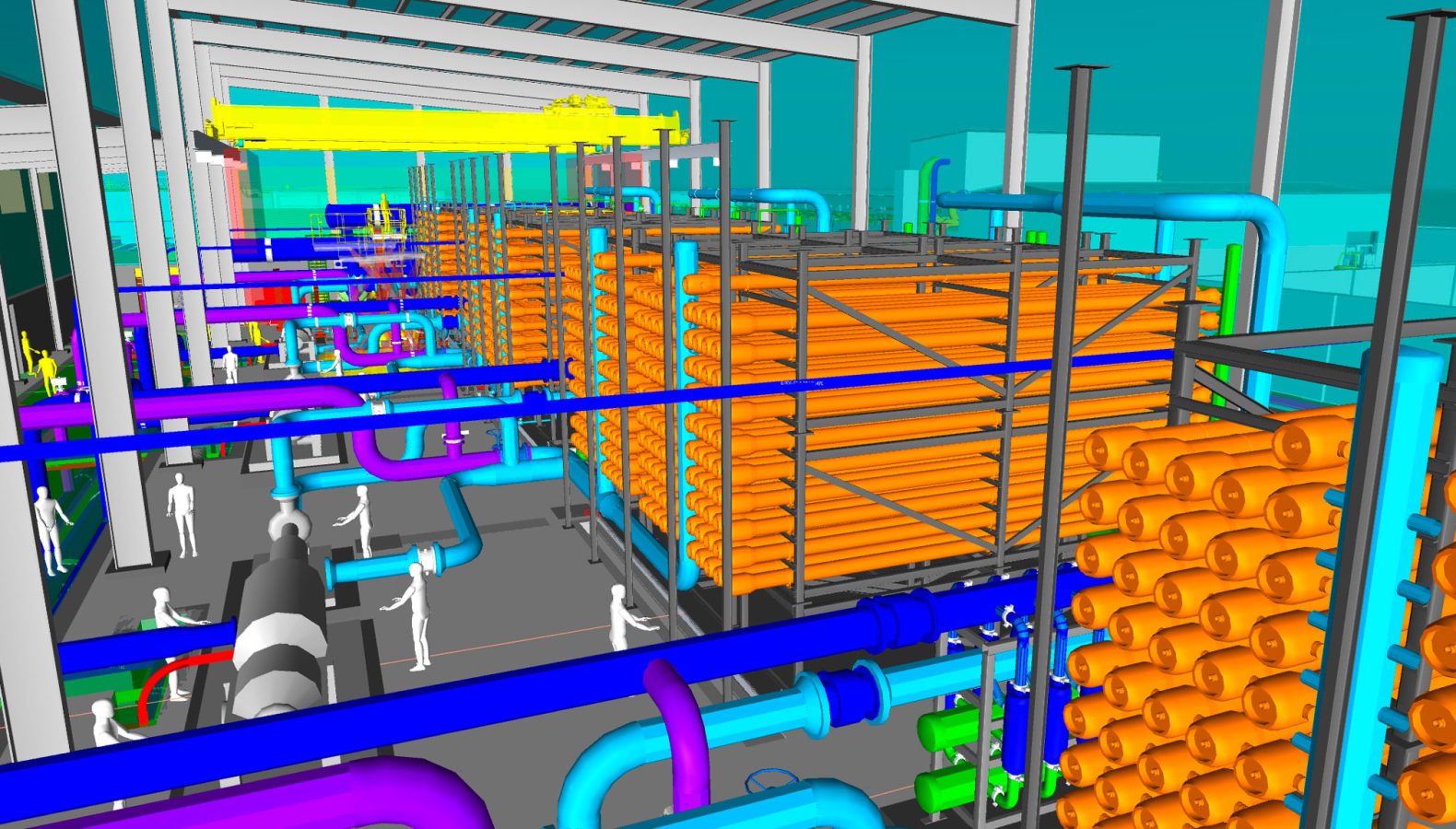

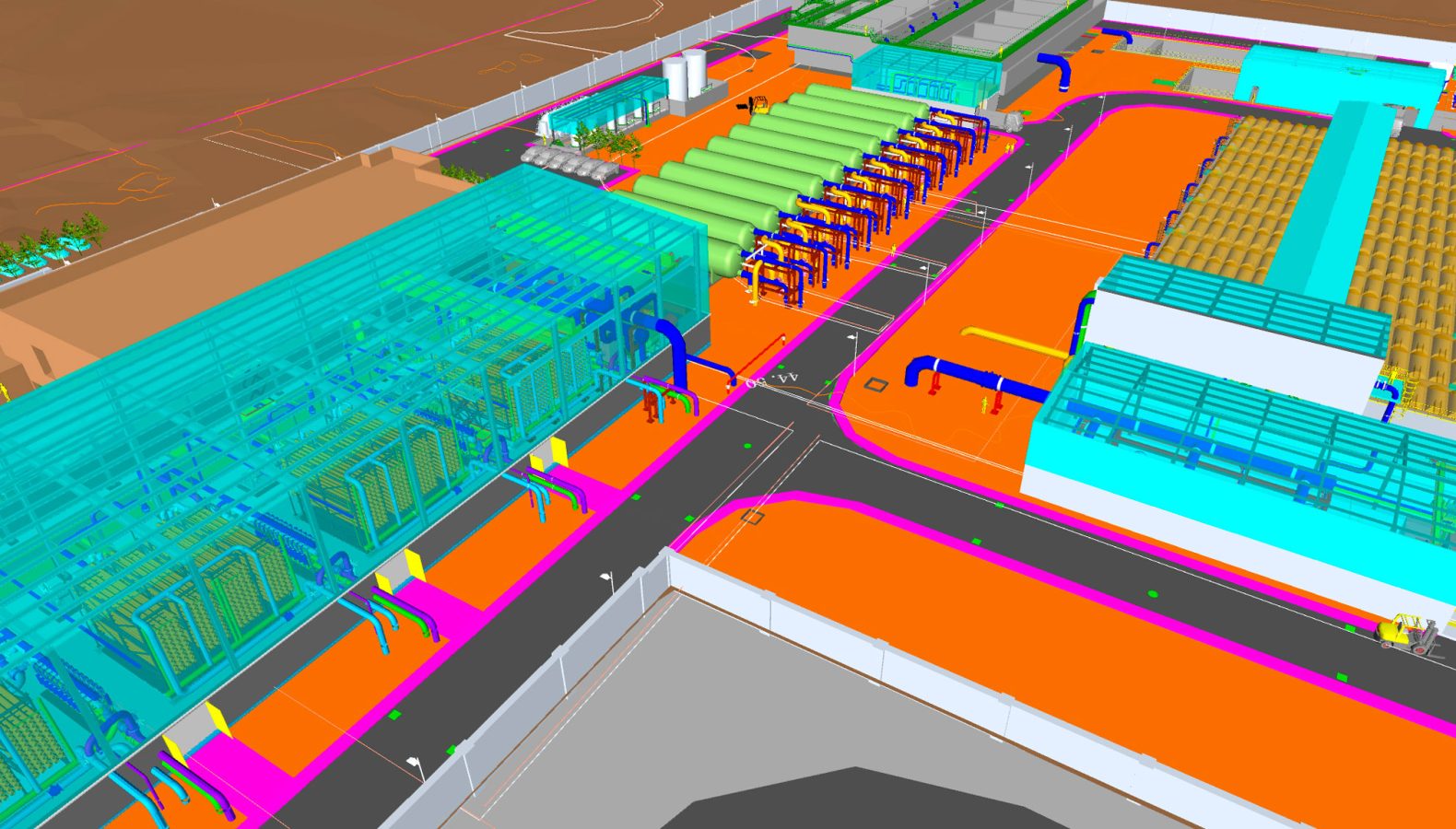

It is a sea water desalination plant that uses reverse osmosis with a production capacity of 113,650 m3/day. The scope of the EPC company includes SeaWater Intake, Brine outfall and a new RO plant. The plant is particularly innovative for its use of Dissolved Air Flotation (DAF) technology as pre-treatment and Gravity Limestone Contactors technology for post-treatment.

A lot of SAVENER’s expertise in Desalination plants was deployed for this project, with a first-rate team of technicians from different areas taking part, such as Design, Electricity, HVAC, Instrumentation & Control and Project Management.

The work carried out by the Electricity Department and Instrumentation & Control in relation with basic engineering, but also equipment purchasing management was of special merit, perfectly integrated with the teams from Abengoa and Fisia. The process of purchasing all the components for these elements, such as power transformers, high and low voltage cabins, CCM, LVS, Switchboards, Frequency Variators, UPS, lightning protection, etc., was handled by SAVENER

SAVENER is accustomed to working with the world’s main EPCs in this sector and ensures that all its technicians have great capacity to integrate into any development team and any area to create an effective and efficient working team.

The seamless integration of the SAVENER team into the workflow with technicians from Abengoa and the client has been remarkable, especially in Piping, where SAVENER has shown flexibility and agility in adapting to the necessary variations and adjustments in time and form demanded by the process managers and during implementation.