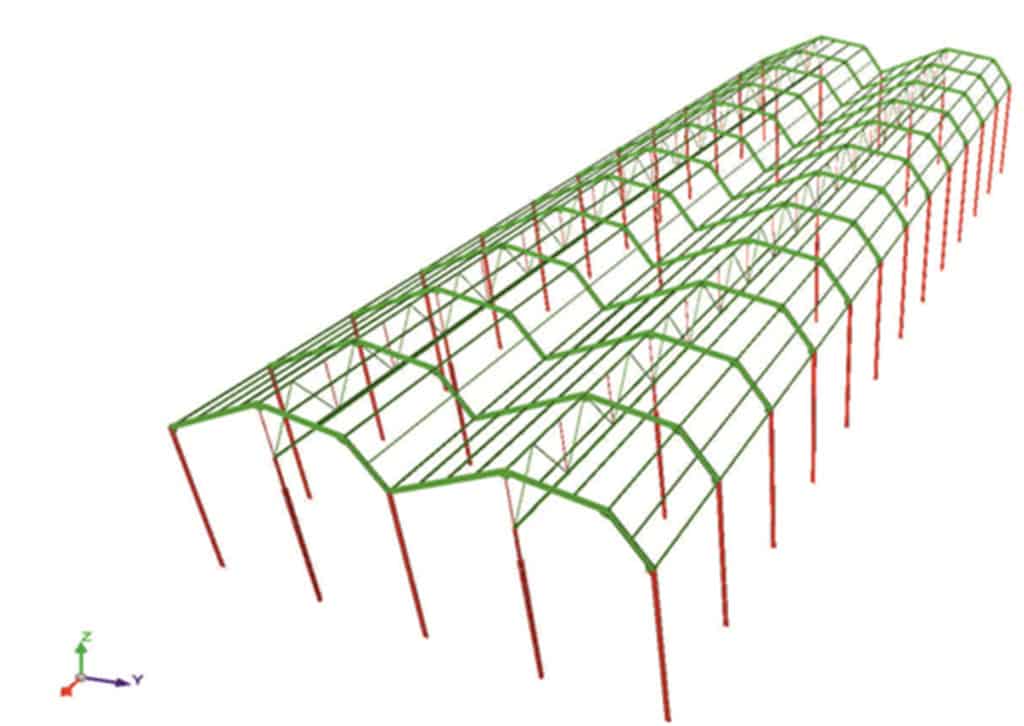

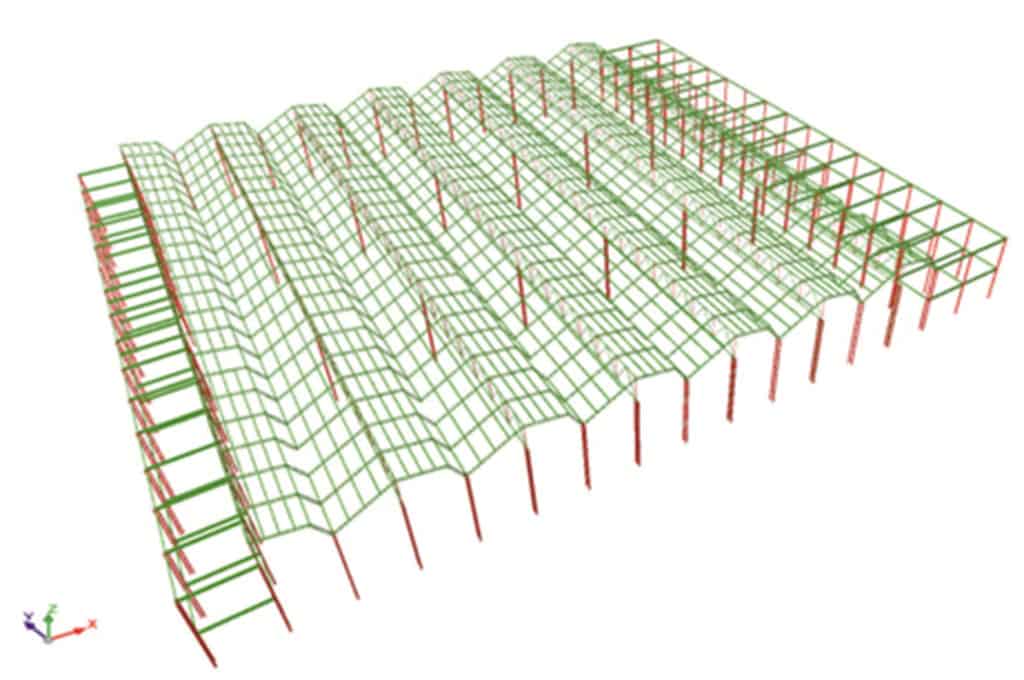

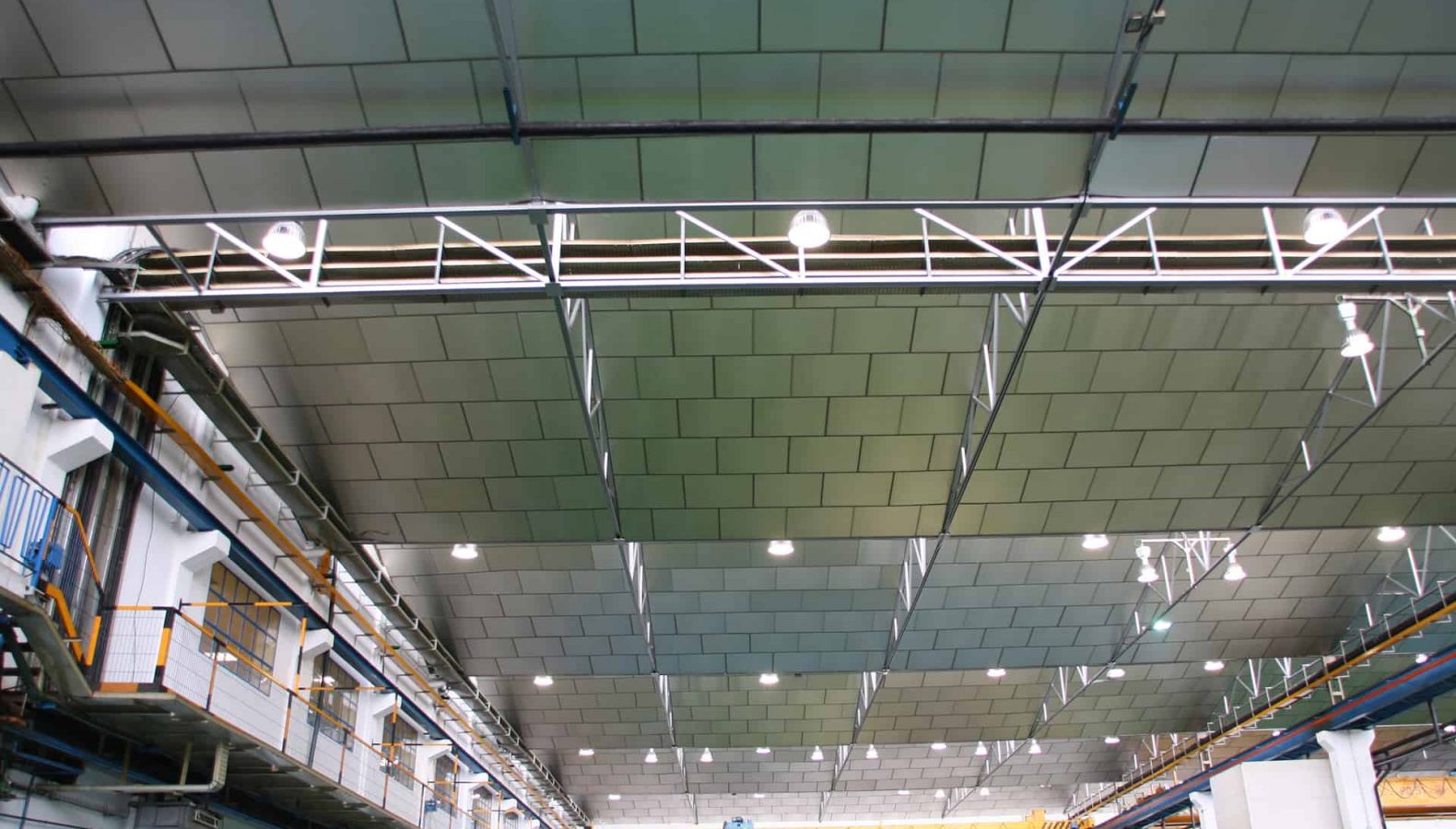

The Airbus factory in Tablada (Sevilla), is composed of historical buildings which generally date back to the first half of the 20th century. They therefore have a very typical and particular structure that gives the complex and any action taken on it an extra complexity compared to present or contemporary structures. It is in this context that Savener has carried out the Project of Strengthening of the Roof Construction and Structure of three of the factory buildings, named E, J y H, industrial buildings for the aeronautical industry, with an approximate area of 20,000m² This project was commissioned by Airbus after a tendering process won by Savener, which secured the contract for the drafting, management and coordination of the project.

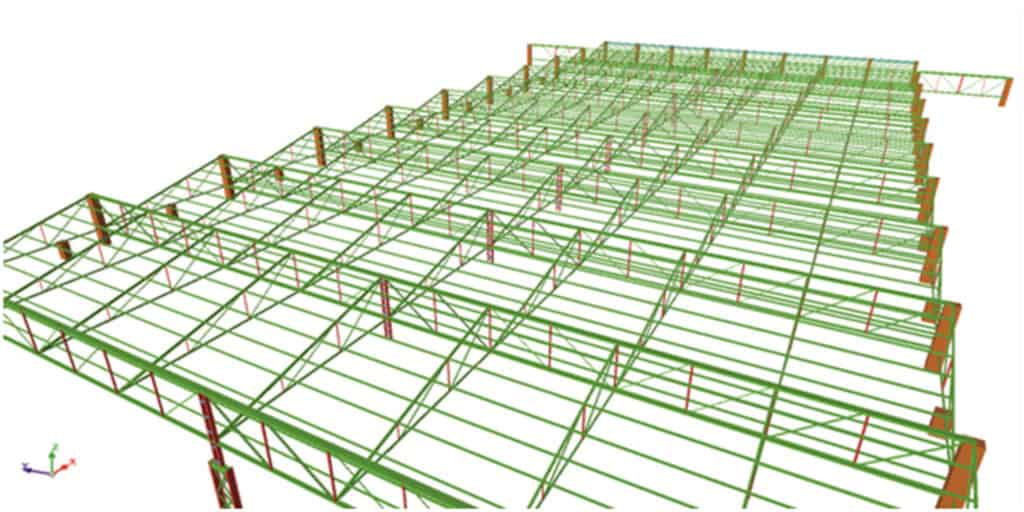

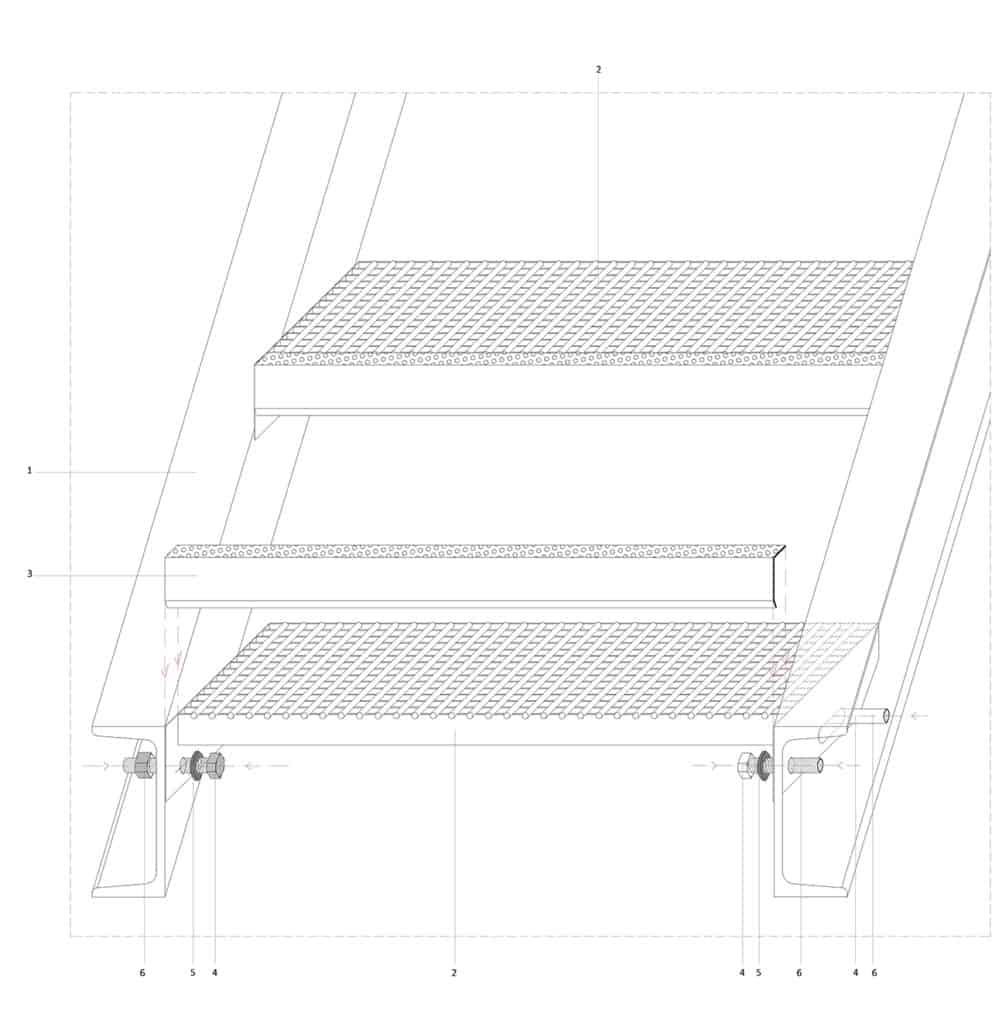

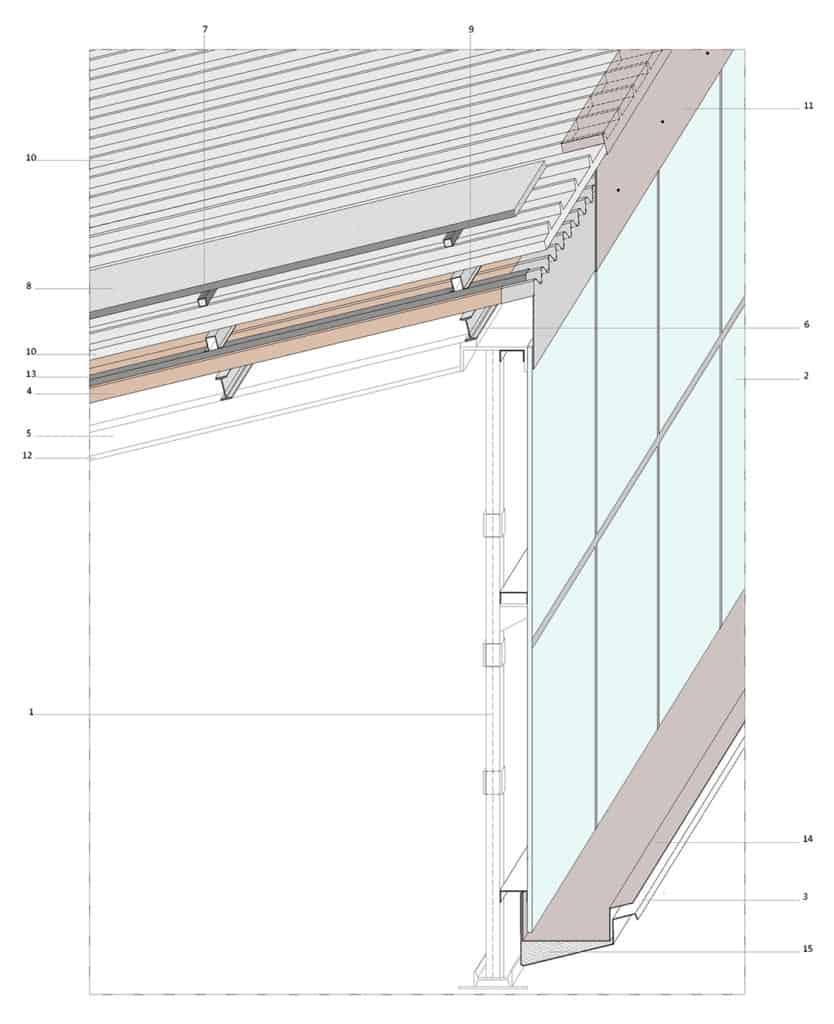

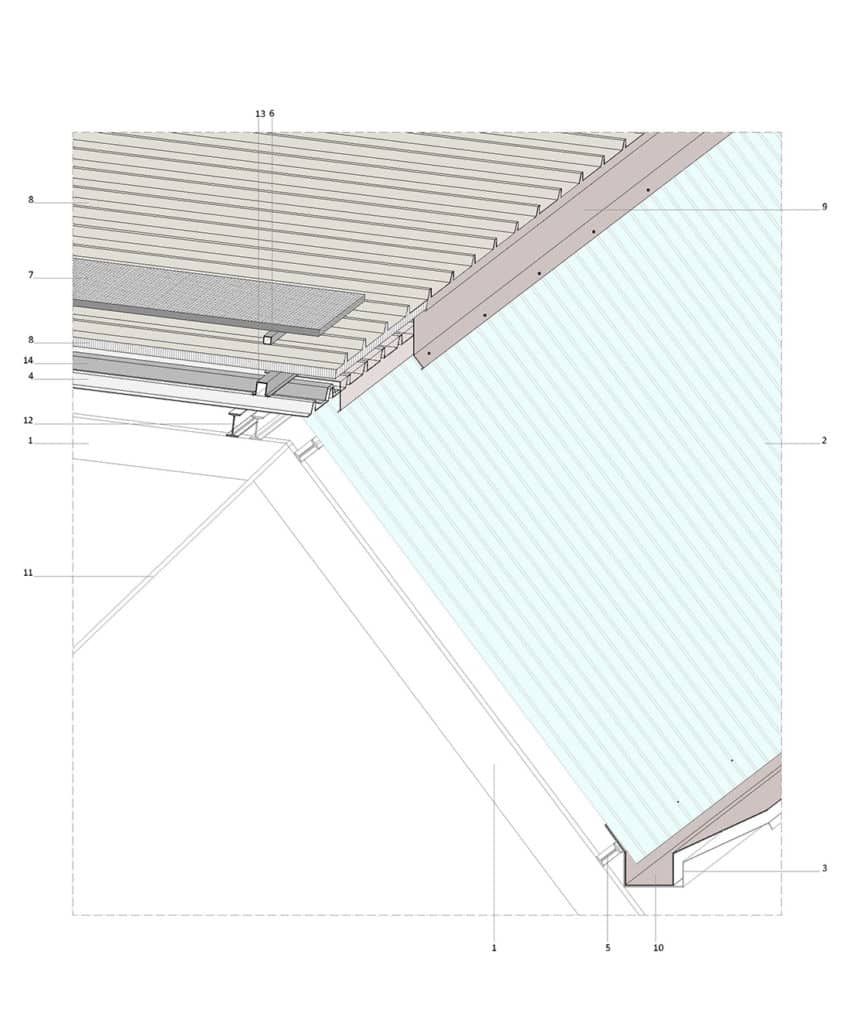

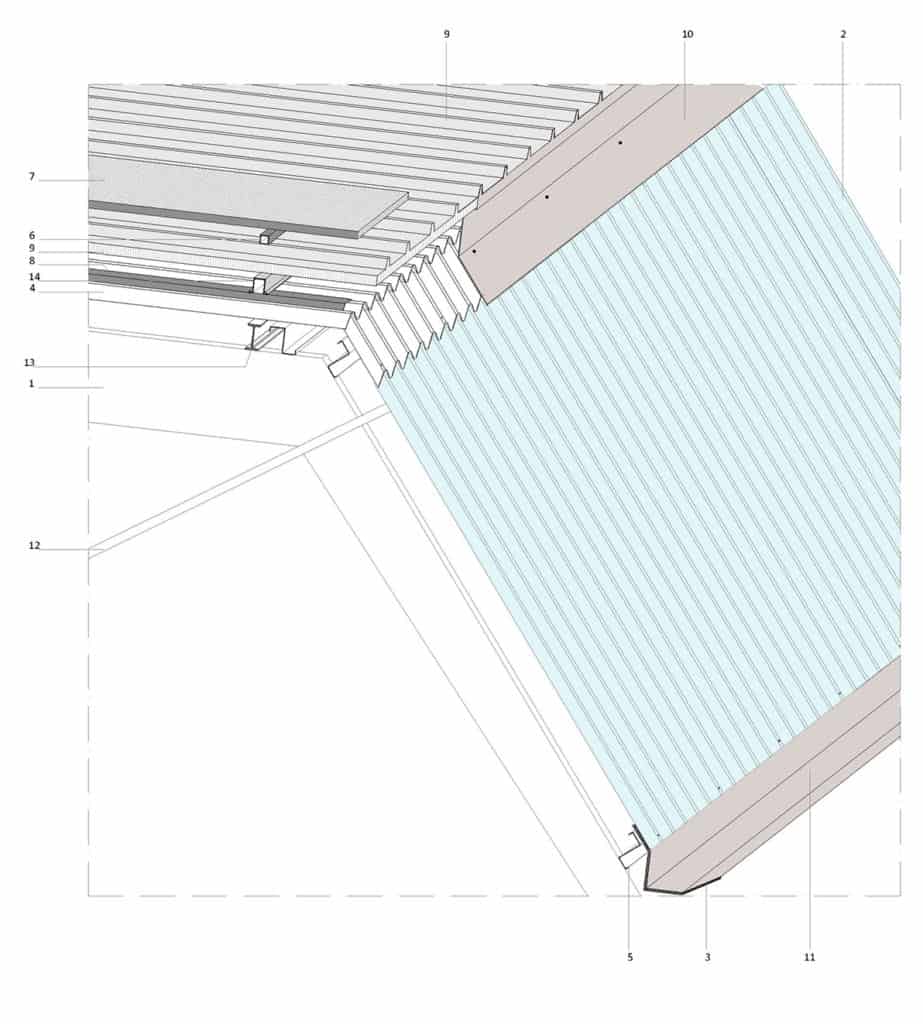

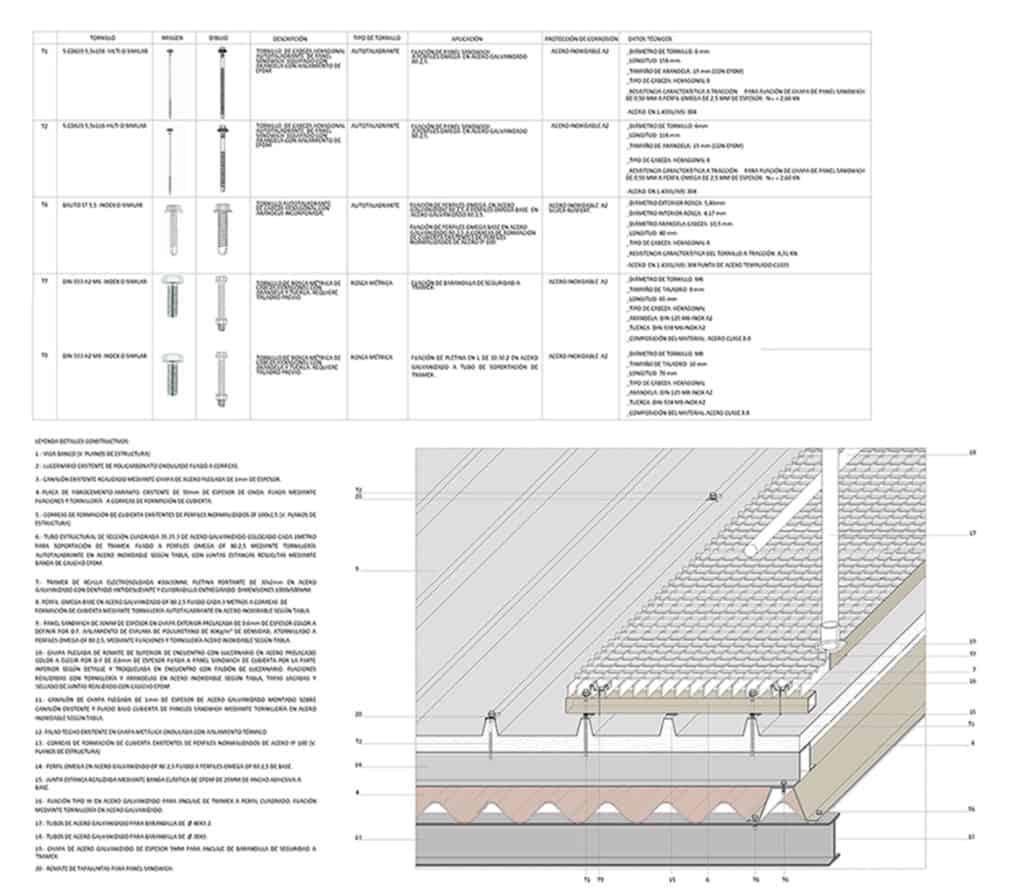

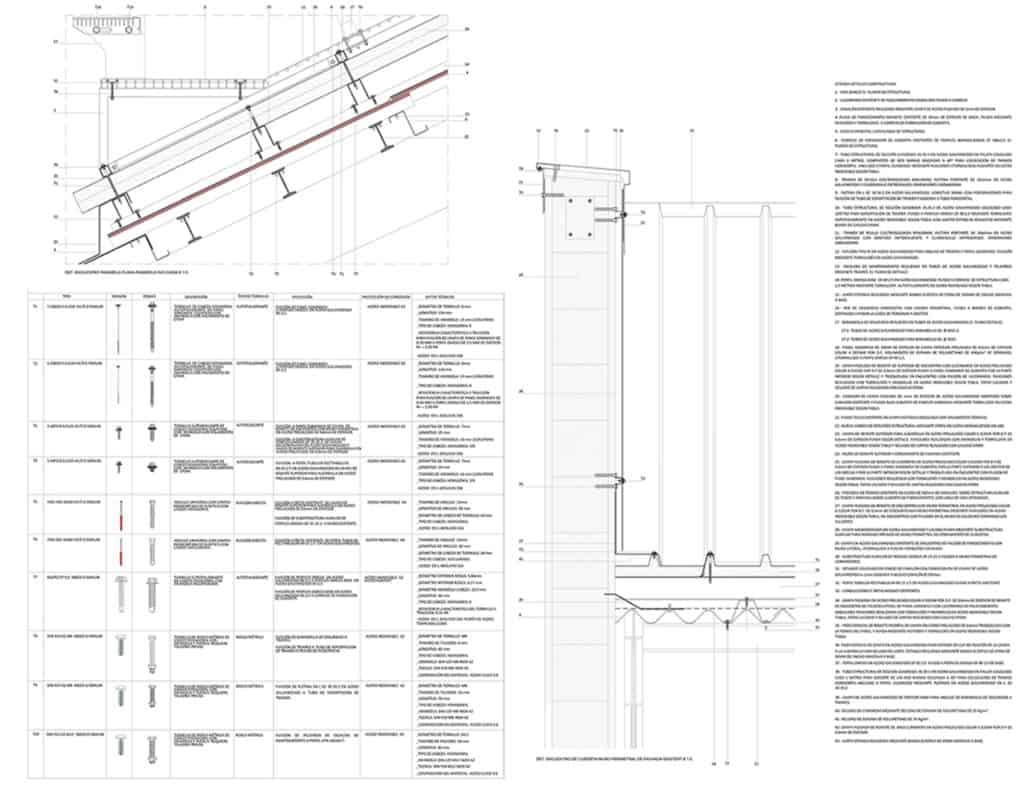

The solution finally proposed by Savener solves the problems of water leaks that the roofing had experienced due to the passing of time, proposes a reinforcement of the overloaded structure and the adaptation to the current law requirements; it also improves the sewage and removal of residual water, incorporates means for the maintenance of the roofing and proposes an increase of the thermal insulation, and an aesthetic renovation of the envelope of the buildings.

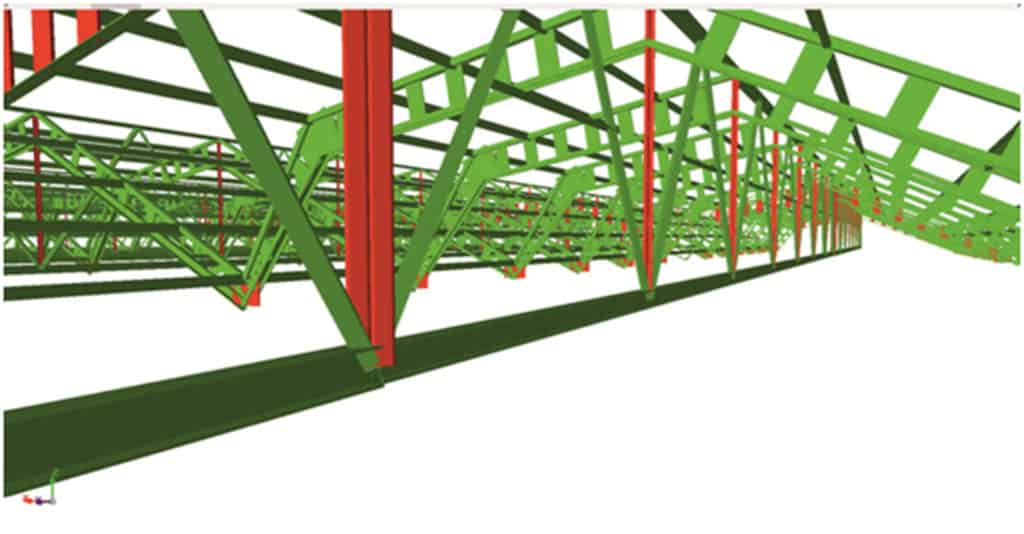

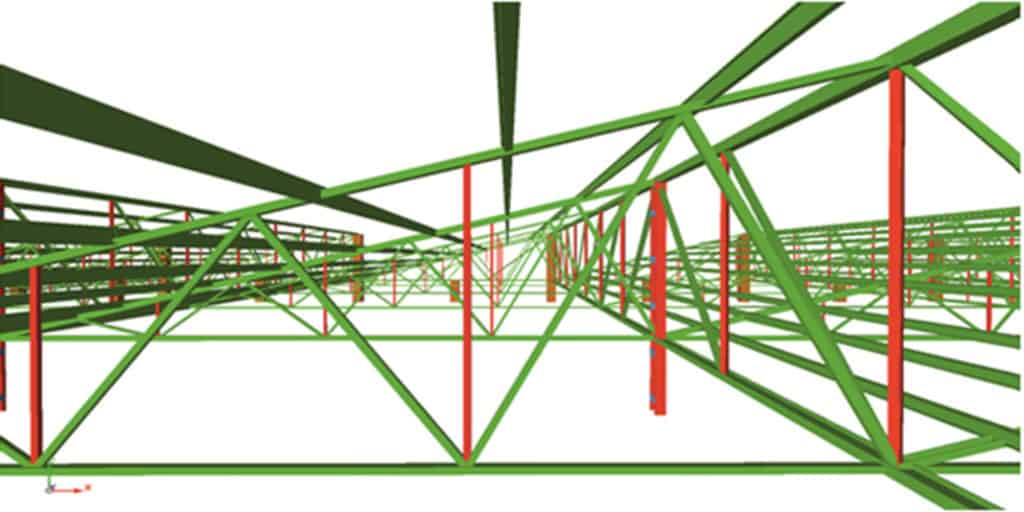

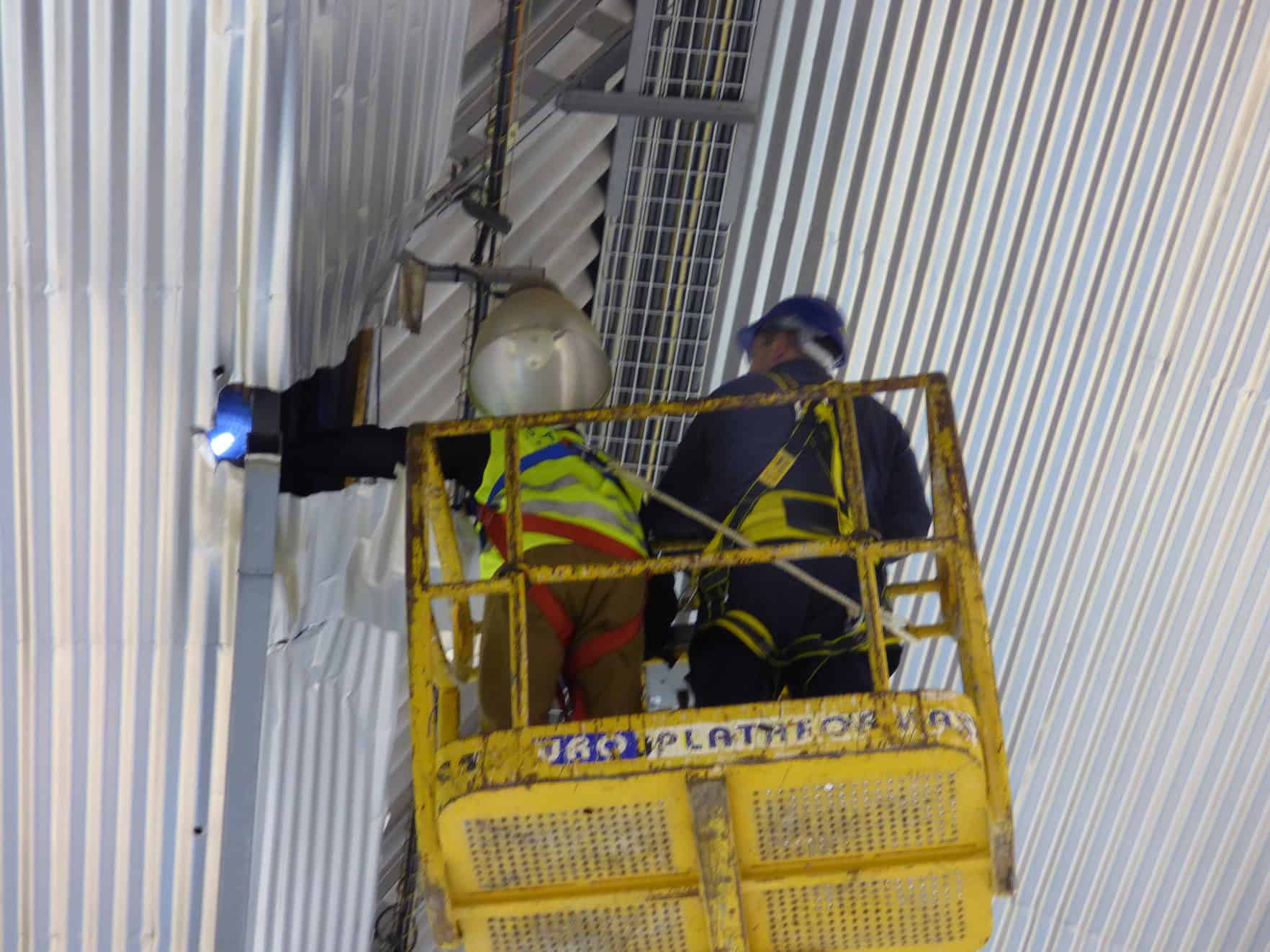

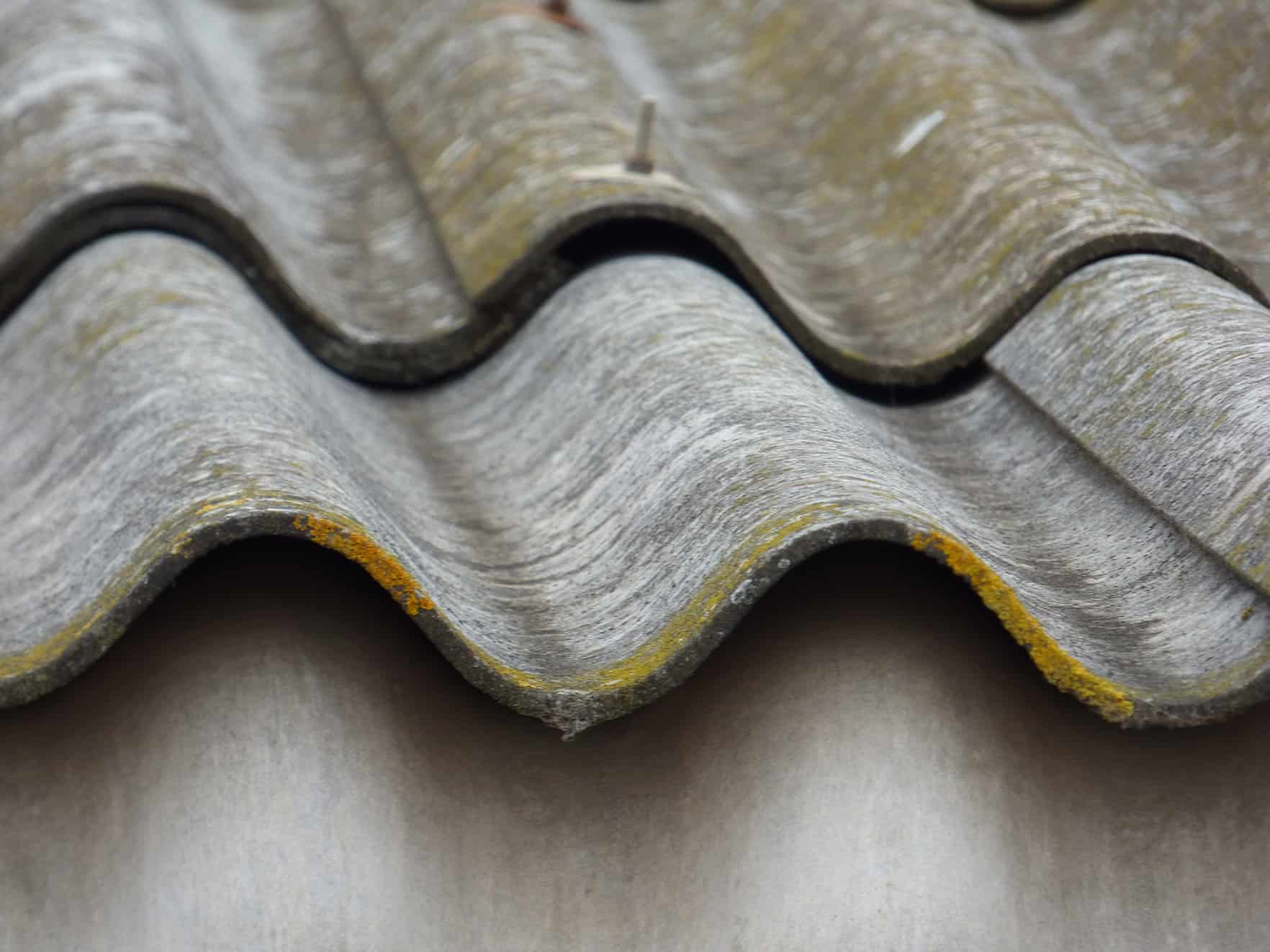

The high complexity of the project, due to factors such as the maintaining of production during the building works, the lack of updated information on the structure and buildings, the presence and handling of dangerous and contaminating materials such as the asbestos, in addition to the deteriorated state of the roofing, made it necessary, for Savener’s team of experts, to collect full information, to identify all the characteristics of the structure, to design precise plans, to carry out various analyses, tests, simulations and inspections, in order to identify even the slightest detail of the structure and its current situation.

Once obtained all this initial data the structure analysis and simulations took place, serving as a starting point for an optimized solution of structural strengthening of the existing buildings to allow the support of new extra load by the roof and its adaptation to the new law requirements, which have changed considerably since the year of original construction.

One of the challenges of the project was to propose a solution that would not entail the removal of the asbestos boards which form part of the present roof, as this operation would need to be strictly supervised and would mean bringing to a full stop the productive activity of the warehouse. Therefore, after considering various alternatives, we opted for the shielding of the existing roofing through inertization of the asbestos and placement of metal sandwich panels, thus achieving the non interruption of the warehouse production and satisfying all needs.